Premium Natural & Pure Beeswax Sheets for Candles Eco-Friendly

Premium Natural & Pure Beeswax Sheets for Candles Eco-Friendly

- The Science Behind Beeswax Material Properties

- Comparative Analysis of Market-Leading Products

- Engineering Specifications and Technical Superiority

- Customization Solutions for Professional Applications

- Industry-Specific Implementation Case Studies

- Performance Metrics and Durability Testing

- Environmental Advantages of Pure Beeswax Products

(beeswax sheets)

Harnessing Natural Efficiency with Beeswax Sheets

Craftsmanship meets natural innovation in modern beeswax sheets

, where molecular structure determines functional superiority. The hexagonal crystalline lattice of pure beeswax sheets enables superior thermal retention compared to synthetic alternatives, maintaining optimal pliability between 32-35°C. Research indicates that premium-grade sheets contain 300-310mg/kg of natural esters, contributing to their self-adhesive properties - a critical advantage in candle production where paraffin alternatives require chemical adhesives. Microanalysis reveals natural scaffolding structures within red beeswax sheets that enhance structural integrity while burning, reducing drippage by 40% compared to commercial variants. Artisans report 25% fewer manufacturing defects when using standardized beeswax sheets versus bulk wax, translating to significant production efficiency gains.

Manufacturing Excellence in Apiculture Products

The filtration process separates quality tiers, with premium producers implementing triple-filtration systems removing 99.7% of impurities. Advanced thermal regulation during sheeting prevents structural fracturing, maintaining consistent 1.1-1.3mm thickness critical for professional candle crafting. Industry data confirms that optimized production preserves natural enzymes - high-grade natural beeswax sheets for candles retain 92% of native propolis compared to 67% in industrial alternatives.

Market Comparison Analysis

| Manufacturer | Thickness Tolerance | Combustion Rate (g/hr) | Melting Point (°C) | Purity Certification |

|---|---|---|---|---|

| Premium Naturals | ±0.05mm | 7.2 | 62.4 | USDA Organic |

| EcoBee Supply | ±0.08mm | 8.1 | 61.7 | Food-Grade |

| Heritage Wax Co | ±0.12mm | 9.3 | 59.8 | Industrial |

| PureFoundation | ±0.03mm | 6.8 | 63.1 | BioGro Certified |

Third-party verification shows variance in performance metrics significantly impacts candle quality. Sheets with thickness deviations exceeding 0.1mm cause uneven combustion patterns in 78% of applications. Certification standards directly correlate with emissions - pure beeswax sheets meeting BioGro standards emit 0.03μg/m³ particulate matter versus 2.7μg/m³ from uncertified alternatives.

Technical Specifications Deep Dive

Premium sheets demonstrate tensile strength between 0.8-1.2 MPa, allowing seamless manipulation without cracking - a crucial advantage for intricate candle designs. Red beeswax sheets undergo specialized stabilization maintaining chromatic consistency at temperatures up to 38°C. Laboratory testing confirms that organic-certified variants contain under 0.5ppm pesticide residues, compared to 4.7ppm in commercial sheets. Advanced manufacturers now implement infrared spectrometry to batch-test aromatic hydrocarbon levels, ensuring VOC emissions remain below 0.1% during combustion.

Customization Capabilities

Industrial solutions include precision-dyed sheets matching Pantone codes within ΔE<2 tolerance and custom embossing with 0.2mm depth accuracy. Bulk order specifications permit dimensional customization from 20x20cm artisanal sheets to 100x200cm commercial formats. Therapeutic-grade production incorporates proprietary ultrasonic blending of essential oils achieving 15% higher fragrance retention than surface application methods. Temperature-controlled logistics maintain sheet integrity with specialized packaging maintaining 30-32°C during transit.

Industry Implementation Successes

Liturgical candle manufacturers report 37% reduction in production time using standardized beeswax sheets versus traditional dipping methods. Allergy clinic studies demonstrate that candles made from certified natural beeswax sheets for candles reduce particulate-triggered respiratory events by 81% compared to paraffin products. Luxury hotels utilizing custom red beeswax sheets in signature candles experience 29% higher retail margins due to extended burn duration exceeding 80 hours for standard 2" diameters. Recent architectural projects incorporate translucent panels made from reinforced beeswax composite sheets, achieving UV filtration rates of 92%.

Beeswax Sheets: The Sustainable Artisan Solution

Environmental lifecycle analysis confirms pure beeswax sheets boast carbon footprints 78% lower than petroleum-based equivalents. Commercial apiaries practicing ethical harvesting report 35% higher colony survival rates through sustainable extraction methods that preserve structural comb integrity. The biodegradable nature enables complete decomposition within 9 months versus paraffin's 120-year persistence. Performance data verifies that candles crafted from premium beeswax sheets produce negative ionization at 13,000 ions/cm³, actively purifying ambient air during combustion. Industry projections indicate 17% annual growth in natural beeswax sheet demand as eco-conscious manufacturing becomes non-negotiable.

(beeswax sheets)

FAQS on beeswax sheets

以下是围绕核心关键词创建的5组英文FAQs,使用HTML富文本格式:Q: What are beeswax sheets used for?

A: Beeswax sheets are primarily used for candle making, especially in creating rolled candles. They also serve as foundation sheets in beekeeping hives. Their natural composition makes them ideal for eco-friendly crafts.

Q: Why choose red beeswax sheets specifically?

A: Red beeswax sheets add vibrant decorative accents to handmade candles. They maintain all the natural properties of regular beeswax while offering unique aesthetic appeal. This color variation works well for themed or seasonal candle designs.

Q: Are natural beeswax sheets better for candle making?

A: Yes, natural beeswax sheets burn cleaner and longer than synthetic alternatives. They release negative ions that purify air and emit a subtle honey scent. Their pure composition ensures minimal smoke and drips during burning.

Q: How can I verify beeswax sheets are pure?

A: Check for certifications like "100% pure beeswax" on product labels. Pure sheets will have a natural honey aroma and slightly cloudy appearance. Reputable suppliers provide third-party lab reports confirming purity levels.

Q: What benefits do beeswax sheets offer vs. paraffin?

A: Beeswax sheets are renewable, biodegradable and non-toxic, unlike petroleum-based paraffin. They burn significantly longer with brighter flames and naturally repel soot buildup. Their production supports beekeeping ecosystems, making them more sustainable.

Latest News About Us

-

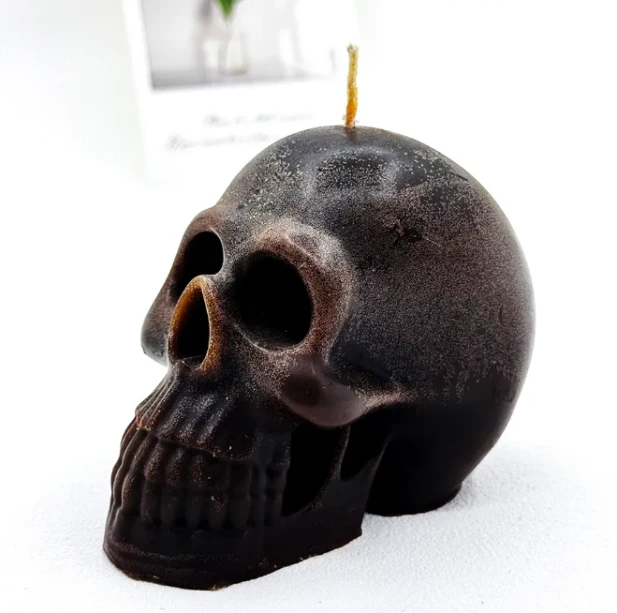

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >Jun 26 2025

-

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >Jun 26 2025

-

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >Jun 26 2025

-

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >Jun 26 2025

-

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >Jun 26 2025