Crystal Candle Dish: Lead-Free Crystal Material Sourcing

Crystal Candle Dish: Lead-Free Crystal Material Sourcing

At Ounis Candle Company, we take pride in crafting premium glass candle plate products, elegant crystal candle dish collections, and durable glass plate candle holders using only the highest quality lead-free materials. Our commitment to safety and luxury drives every aspect of our crystal candleware production, from ethical material sourcing to precision manufacturing processes.

Material Selection for Glass Candle Plate Products

- Our glass candle plate collection uses only eco-friendly soda-lime glass containing 72% silica for optimal clarity and thermal stability.

• The crystal candle dish line features lead-free potassium crystal with 24% minimum lead oxide alternative for brilliant refraction.

• All glass plate candle holders undergo X-ray fluorescence testing to verify complete absence of heavy metals and toxic elements.

• The glass candle plate raw materials include 30-40% recycled glass content without compromising optical quality.

• Our crystal candle dish formula incorporates barium oxide instead of lead to achieve comparable brilliance safely.

|

Produktname |

Klarer transparenter Kerzenteller, runder Kerzenhalter aus Glas |

|

Farbe |

Transparent oder in Sonderfarben |

|

Besonderheit |

Kerzenhalter zur Hochzeit |

|

Größe |

10*10*1,25 cm |

|

Material |

Glass |

|

Gelegenheit |

Wedding.home decoration |

|

Packliste |

Glass tealight candle holder × 360pcs,or customized package |

|

Ausführungstyp |

Poliert |

Manufacturing Process for Crystal Candle Dish

- Each crystal candle dishbegins as molten glass at 1500°C, hand-gathered by master glassblowers using traditional techniques.

• The glass candle plateproduction line utilizes precision press-molding technology that maintains ±0.3mm thickness consistency.

• Our glass plate candle holders undergo slow annealing over 36 hours in computer-controlled ovens to prevent internal stresses.

• The crystal candle dish polishing process involves 5-stage diamond abrasives that achieve optical-grade surface finishes.

• Quality inspectors examine every glass candle plate under polarized light to detect any imperfections before packaging.

Quality Standards for Glass Plate Candle Holders

- All glass plate candle holdersmeet FDA food-contact standards and European REACH chemical safety regulations.

• The crystal candle dishproducts undergo rigorous thermal shock testing between 0°C and 120°C water baths.

• Our glass candle plate thickness is laser-verified at 5 points to ensure uniform 5mm±0.2mm dimensions.

• The glass plate candle holders base stability is tested with 200g weights at 15° angles to prevent tipping.

• Every crystal candle dish is checked for optical clarity using standardized light transmission measurements.

Design Features of Crystal Candle Dish

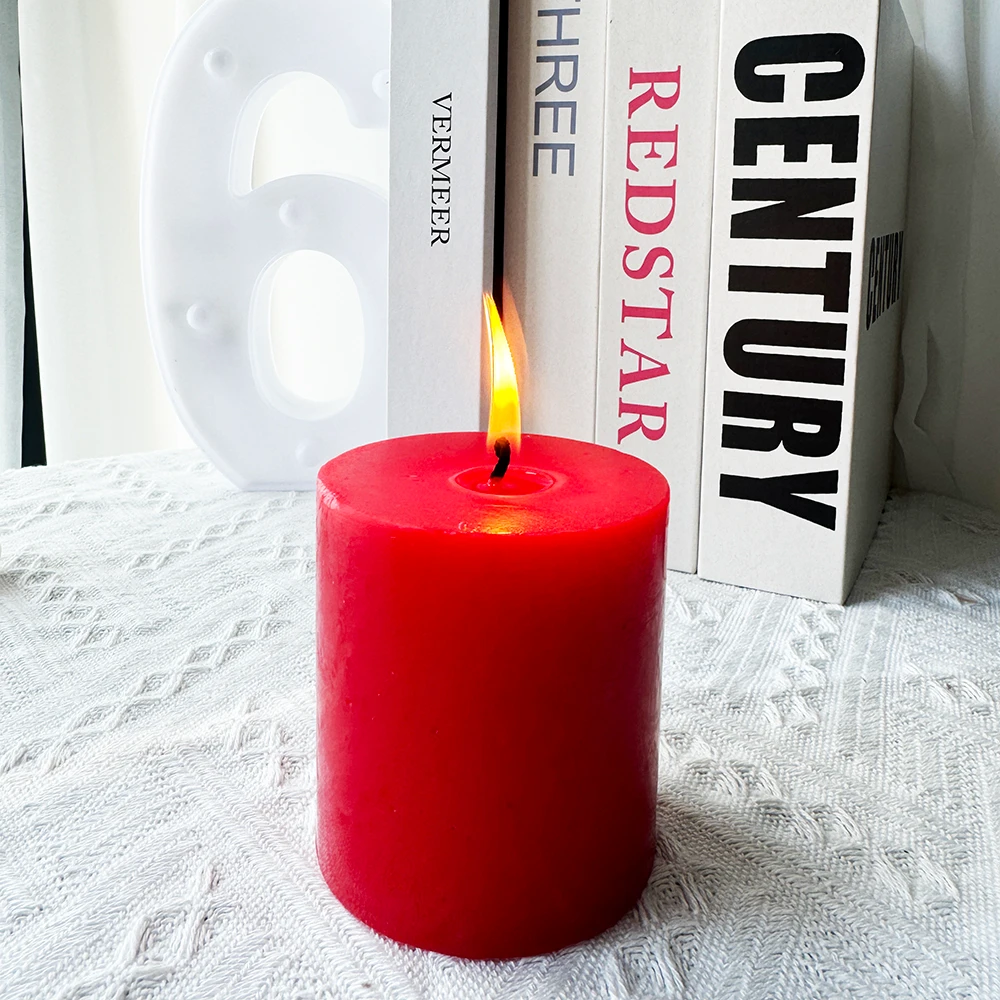

- The crystal candle dishcollection features 15 elegant designs from minimalist rounds to ornate cut patterns.

• Our glass candle plateedges are precision-fire-polished for smoothness and chip resistance.

• The glass plate candle holders include subtle anti-slip silicone dots on the base for added stability.

• Special crystal candle dish light-refracting cuts enhance candle glow without requiring lead content.

• All glass candle plate products are designed to fit standard 3" diameter pillar candles perfectly.

Packaging and Safety for Glass Plate Candle Holders

- Each glass plate candle holdersships in individual recyclable PET foam protectors within gift-ready boxes.

• Our crystal candle dishcollections include care instructions for maintaining optical clarity long-term.

• The glass candle plate wholesale packaging uses compartmentalized dividers to prevent transit damage.

• Safety warnings about proper candle use accompany all glass plate candle holders shipments.

• Luxury crystal candle dish gift sets include microfiber polishing cloths for maintenance.

Glass Candle Plate FAQs

Q: What glass materials are ideal for heat-resistant glass candle plate production?

A: Borosilicate glass is preferred for glass candle plate due to its low thermal expansion, preventing cracks from candle heat. Soda-lime glass works for basic designs but requires 3-5mm thickness for safety, while tempered glass adds durability for commercial use.

Q: How does crystal candle dish production influence glass plate design?

A: Crystal candle dish techniques like lead-free crystal cutting and faceting inspire premium glass candle plate designs. Manufacturers use diamond-tipped tools to create faceted edges or engraved patterns, blending crystal elegance with glass affordability in plate production.

Q: What quality controls ensure glass plate candle holders meet safety standards?

A: Each glass plate candle holder undergoes thermal shock testing (100°C to 20°C) to verify heat resistance and ultrasonic scanning for uniform thickness. Burn tests simulate 4-hour use to check for warping, while edge smoothness is inspected to prevent chipping.

Q: Can custom logos be added to glass candle plate during production?

A: Yes—custom logos on glass candle plates are achieved via sandblasting, screen printing, or acid etching. For bulk orders, manufacturers use custom molds with embedded logo designs, while small batches opt for post-production decals, balancing cost and personalization.

Q: How do production costs differ for glass plate candle holders vs. plain plates?

A: Glass plate candle holders cost 15-30% more than plain plates due to embedded metal/silicone holders and multi-component assembly. Manufacturers reduce costs by integrating holder molds during glass forming, while premium crystal-inspired designs with faceted edges command higher prices.

Light Up Your World with Ounis Candle

Welcome to Ounis (Shijiazhuang) Import&Export Co., Ltd. https://www.ouniscandle.com/ For over a decade, Ounis has crafted sensory magic in Shijiazhuang—turning premium wax and global fragrances into art. From lavender-scented glass jars to beeswax pillars, LED flameless flickers to birthday candle whimsy, our range sparkles. Customize via ODM/OEM, from scents to shapes. Exported worldwide, we blend integrity with innovation. Join us—where every candle tells a story.

Aktuelles über uns

-

The Warm Glow of Everyday Comfort: Inside the World of Candle MakingWhen was the last time you truly relaxed? Maybe it was while watching the flame of a soft candle flicker gently in a quiet room, or catching a calming lavender scent waft through your home after a long day.Read More >

The Warm Glow of Everyday Comfort: Inside the World of Candle MakingWhen was the last time you truly relaxed? Maybe it was while watching the flame of a soft candle flicker gently in a quiet room, or catching a calming lavender scent waft through your home after a long day.Read More >Aug 21 2025

-

Scented Serenity: Elevate Ambience With Glass CandlesIn the world of home decor and personal wellness, the allure of a scented glass candle lies in its ability to combine visual elegance with fragrant comfort.Read More >

Scented Serenity: Elevate Ambience With Glass CandlesIn the world of home decor and personal wellness, the allure of a scented glass candle lies in its ability to combine visual elegance with fragrant comfort.Read More >Aug 21 2025

-

Lighting The Future: Bulk Flameless Candles for Elegant AmbienceIn a world increasingly conscious of both safety and sustainability, flameless candles have emerged as the elegant, smoke-free solution for modern ambiance.Read More >

Lighting The Future: Bulk Flameless Candles for Elegant AmbienceIn a world increasingly conscious of both safety and sustainability, flameless candles have emerged as the elegant, smoke-free solution for modern ambiance.Read More >Aug 21 2025

-

Candle Holder Mirror Plate For Elegant Decor AccentsWhen you’re designing a tablescape that demands elegance, adding a candle holder mirror plate instantly enhances the entire visual impact.Read More >

Candle Holder Mirror Plate For Elegant Decor AccentsWhen you’re designing a tablescape that demands elegance, adding a candle holder mirror plate instantly enhances the entire visual impact.Read More >Aug 21 2025

-

Elegant 3 Piece Candle Holders for Every HomeLooking for a touch of luxury to elevate your space without breaking the bank? A 3 piece crystal candle holder set is more than just a decorative piece—it's an expression of elegance.Read More >

Elegant 3 Piece Candle Holders for Every HomeLooking for a touch of luxury to elevate your space without breaking the bank? A 3 piece crystal candle holder set is more than just a decorative piece—it's an expression of elegance.Read More >Aug 21 2025