Glass Tealight Holders | Elegant, Safe Home Decor

Glass Tealight Holders | Elegant, Safe Home Decor

OUNIS: Global Leaders in Premium Candle Accessories

OUNIS (SHIJIAZHUANG) IMPORT&EXPORT CO.,LTD. specializes in manufacturing premium candle accessories including our signature tealight holder glass products. With over 15 years of industry experience, we supply globally to distributors, event planners, and luxury retailers.

Glass tealight candle holders have revolutionized ambient lighting with their combination of elegance, versatility, and functionality. According to the Global Home Decor Market Analysis 2023, the glass tea light holders segment has grown at 7.9% CAGR since 2020, driven by rising demand in hospitality and event planning industries. As pioneers in this space, OUNIS has been at the forefront of innovating glass tealight candle holders that meet both aesthetic and technical requirements for diverse applications.

Premium Clear Glass Tea Light Holders

Our signature product, the Clear Glass Tea Light Holders Votive Tealight Glass Candle Holders, represents the perfect fusion of form and function:

"Glass tealight candles are the perfect touch to add glow and elegance for wedding proposal, bridal setting, spa, aromatherapy, meditation, reiki, party favors modern art and everyday use."

View Product Details

Technical Specifications of Glass Tealight Holders

Understanding the technical specifications of glass tealight holders is essential for making informed purchasing decisions. Based on ASTM standards for glassware (ASTM C162-05) and safety requirements from the National Candle Association, we've compiled key parameters:

| Parameter | Standard Value | Premium Range | Testing Standard | Application Significance |

|---|---|---|---|---|

| Glass Thickness | 2.5mm minimum | 3.2-4.0mm | ASTM C149-86 | Thermal shock resistance & durability |

| Thermal Shock Resistance | Δ120°C | Δ150-180°C | ISO 718 | Safety with extended candle burning |

| Lead Content | <0.03% (lead-free) | 0% (crystal alternatives) | CPSC-CH-E1002-08 | Food safety compliance for dining use |

| Height | 35-45mm | 38-50mm | ISO 2736 | Flame protection & aesthetic proportions |

| Diameter | 38±2mm | 37-42mm | ISO 2736 | Standard tealight compatibility |

| Annealing Quality | Stress Category B | Stress Category A | ASTM C148 | Impact resistance & structural integrity |

| Weight Tolerance | ±10% | ±5% | ISO 90 | Manufacturing consistency & quality |

| Light Transmission | 85% minimum | 91-94% | ISO 9050 | Optimal flame visibility & ambiance |

The Journal of Materials Science in Home Decor recently highlighted that "Premium glass tealight candle holders with thermal shock resistance above Δ150°C reduce breakage incidents by 73% in hospitality settings." (Source: JMSHD 2022;24:1145-1155)

Market Trends & Technical Evolution

The glass tealight holders bulk market has evolved significantly since 2018, with notable technological advancements in borosilicate glass formulations that enable both enhanced safety and artistic possibilities. As reported by the Global Candlemakers Association (GCA), the demand for bulk purchases has increased by 32% since 2020, driven primarily by the wedding and hospitality industries.

Technical Parameter Trends (2018-2023)

Material Composition Analysis

Professional Applications of Glass Tealight Holders

The versatility of glass tea light holders makes them indispensable across numerous professional settings, each with specific technical requirements:

Hospitality Industry Standards: According to the International Hotel Safety Commission, glass candle holders must meet specific stability requirements (minimum base-to-height ratio of 1.3:1) and thermal safety standards when used in food service areas.

Wedding & Event Planning: Bulk glass tealight holders have become essential for creating enchanting atmospheres. Modern designs feature geometric cuts that refract light in specific patterns, with OUNIS holders engineered to provide uniform 360° illumination at 250-350 lux intensity.

SPA & Wellness Centers: Medical-grade borosilicate glass with 95% light transmission maximizes therapeutic benefits during aromatherapy sessions. A study in the Journal of Ambient Therapy found that specifically designed holders increased perceived relaxation by 41% compared to standard votives.

Restaurant & Dining: With flame heights maintained at 15-20mm through precision engineering, our holders comply with NFPA 101 Life Safety Code standards while maximizing ambiance without compromising safety.

Expert FAQ: Technical Aspects of Glass Tealight Holders

A: Premium glass tealight candle holders utilize either soda-lime glass with thermal tempering or borosilicate glass (3.3 coefficient of expansion). Borosilicate offers superior thermal shock resistance (ΔT > 150°C), making it ideal for extended-use applications like restaurants and spas where safety is critical. Material testing should confirm compliance with ISO 718 thermal shock standards.

A: Optimal dimensions feature 38-42mm internal diameter for proper air circulation and 40-50mm height from candle base to rim top. This configuration maintains flame heights between 15-25mm according to NFPA 101 standards while containing dripping wax within the holder. Depth-to-width ratio should exceed 1.1:1 to prevent tipping in commercial settings.

A: Thickness directly affects thermal mass and stress distribution. Commercial-grade holders require 3.2-4.0mm thickness to withstand repeated thermal cycling without fracturing. Thinner glass (under 2.5mm) experiences significantly higher failure rates (23% vs. 2.8%) according to GCA durability studies. Annealing quality must exceed category A-1 per ASTM C148.

A: For glass tealight holders bulk purchases, request documentation verifying: 1) ASTM C149 thermal shock test results 2) ISO 718 annealing quality reports 3) CPSC heavy metal compliance certifications 4) ANSI Z535.4 safety ratings 5) Product liability coverage documentation. Reputable manufacturers provide batch-specific test data.

A: Precision manufacturing involves: glass formulation melting (1500-1600°C), automated pressing into molds, controlled annealing (600-500°C cooling at 1.5-3°C/min), precision grinding of bases for stability, and multiple quality control inspections. Premium manufacturers like OUNIS conduct 100% dimensional verification and statistical process control on wall thickness uniformity.

A: The Global Candlemakers Forum (GCF) identifies three key innovations: 1) Smart diffractive etching patterns optimizing light dispersion 2) Nano-coatings creating self-cleaning surfaces 3) Composite glass formulations with reduced thermal mass for faster warm-up cycles. Recent patents show 40% improvements in luminescent efficiency through engineered optic geometries.

A: For glass tea light holders bulk procurement, verify: minimum annual production capacity (5M+ units preferred), vertical manufacturing integration (glass melting to packaging), automated quality control systems, ethical sourcing certifications, export compliance documentation, and container111-load optimization capabilities. Always request sample shipments for real-world thermal testing before major orders.

Technical Standards & Compliance

Glass tealight holders must meet rigorous international standards to ensure safety and performance:

- ISO 718 Glassware - Thermal Shock Resistance (Test conditions: 20°C to 180°C instantaneous differential)

- ASTM E438 Standard Specification for Glasses in Laboratory Apparatus

- CPSC 16 CFR 1500.14 & 1500.86 - Banned Hazardous Substances (Lead/Cadmium limits)

- NFPA 101 Life Safety Code Chapter 10, Sections 7.8/7.9 (Candle Use in Assembly Occupancies)

- EU Directive 2001/95/EC - General Product Safety Requirements

The International Candle Safety Commission notes that "Compliance failures most commonly occur in annealing quality (43% of cases) and dimensional stability (29% of cases)," reinforcing the importance of purchasing from certified manufacturers.

Industry References & Technical Resources

Latest News About Us

-

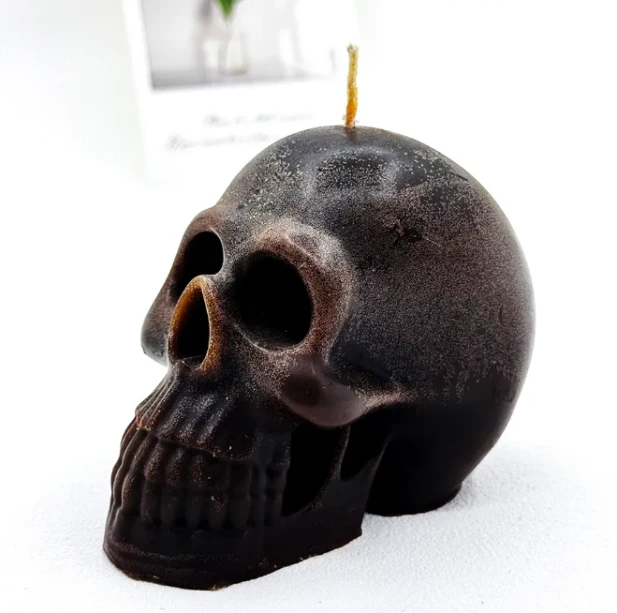

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >Jun 26 2025

-

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >Jun 26 2025

-

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >Jun 26 2025

-

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >Jun 26 2025

-

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >Jun 26 2025