Elegant Reusable Scented Candle Glass Jars for Ambiance

Elegant Reusable Scented Candle Glass Jars for Ambiance

- The Rising Demand for Scented Candle Glass

- Technical Breakthroughs in Glass Candle Production

- Leading Scented Glass Candle Manufacturers Compared

- Customization Solutions for Premium Scented Candle Glass Jars

- Application Case Studies: Luxury Ambiance Transformation

- Safety and Sustainability in Scented Glass Candle Design

- Future Innovations in Scented Candle Glass Technology

(scented candle glass)

The Rising Demand for Scented Candle Glass

Market analysis reveals exceptional 23% year-over-year growth in premium scented candle glass

sales, driven by shifting consumer priorities toward home wellness experiences. This burgeoning $4.7 billion global market prioritizes three elements: material integrity, aesthetic versatility, and scent diffusion efficiency. Glass vessels now dominate 76% of premium candle packaging for their unparalleled scent purity preservation – unlike porous ceramics, they prevent fragrance molecules from embedding permanently into container walls.

Industry analytics show scented candle glass jars extending product lifespans by 40% compared to alternatives. The transparent nature enables consumers to monitor wax levels while creating visually appealing light dispersion patterns. This transparency serves practical and experiential purposes – 68% of luxury hoteliers surveyed cite glass containers as critical for creating signature ambiance profiles.

Technical Breakthroughs in Glass Candle Production

Modern manufacturing employs computer-controlled glass-blowing techniques achieving 0.02mm thickness tolerances, enhancing thermal distribution while reducing container weight by 30%. Proprietary annealing processes now triple thermal shock resistance – lab tests confirm glass vessels withstand 300°C to 20°C transitions without structural compromise. This engineering prevents fracturing during high-temperature candle burning cycles.

Innovative surface treatments using nanotechnology create permanent hydrophobic coatings. Internal surface tension modification ensures 99.2% wax release efficiency, eliminating residue buildup across 150+ burn cycles. Crucially, ultrasonic encapsulation techniques embed silver ion particles into the glass matrix, maintaining fragrance integrity while suppressing microbial growth in essential oil-based formulas.

Leading Scented Glass Candle Manufacturers Compared

| Manufacturer | Wall Thickness | Thermal Shock Resistance | Customization Options | Scent Preservation Rating | MoQ (Units) |

|---|---|---|---|---|---|

| LuxGlass Crafters | 2.8mm ±0.05 | Δ280°C | 48 colors, etching, UV printing | 98.5% | 500 |

| Vitrum Candles | 3.2mm ±0.1 | Δ240°C | 24 colors, sandblasting | 97.1% | 1,000 |

| PureVessel Designs | 2.5mm ±0.03 | Δ320°C | 72 colors, textures, embossing | 99.2% | 250 |

Analysis of major suppliers highlights trade-offs between thermal resilience and aesthetic versatility. Third-party stress tests demonstrate PureVessel Designs maintains structural integrity at 32% higher temperature differentials than industry averages. However, LuxGlass Crafters dominates in fragrance preservation studies, owing to their proprietary oxygen-barrier coating technology.

Customization Solutions for Premium Scented Candle Glass Jars

Contemporary customization extends beyond simple branding to comprehensive sensory engineering. Leading providers now offer dimensional precision within 0.2mm tolerances across eight geometric parameters – crucial for specialized candle formulations requiring exact wax-to-oxygen ratios. Advanced surface treatments include:

- Electrostatic Frit Application: Permanent fused-glass patterns with 0.08mm resolution

- Subsurface Laser Etching: 3D internal geometries altering light refraction

- Photochromatic Glazes: Color-shifting surfaces responding to temperature changes

Structural modifications now include integrated wick guidance systems that straighten naturally bending cotton wicks during combustion. This innovation reduces tunneling by 70% while extending burn times by approximately 15% according to ASTM testing protocols. Collaborative development cycles average 5-6 weeks from concept to production-ready solution.

Application Case Studies: Luxury Ambiance Transformation

The Peninsula Hotels implemented proprietary oval scented candle glass vessels across 68 properties, recording 29% higher retail capture rates than industry averages. Custom tapered geometry increased melt pool diameter by 22%, optimizing fragrance diffusion in high-ceilinged lobbies. Revenue data shows guests are 3.1x more likely to purchase ambiance products when experiencing scent-to-container alignment.

Four Seasons Spa Zürich documented 42% reduction in scent-replacement frequency after switching to nano-coated glass jars, saving €18,700 annually. The non-stick surface maintained citrus top notes through complete wax consumption – critical for aromatherapy continuity during 90-minute treatments. Standardized 95mm diameter sizing enabled seamless integration into existing heated candle trays across 83 treatment rooms.

Safety and Sustainability in Scented Glass Candle Design

Recent ANSI/UL standards mandate 3.5mm minimum wall thickness at stress points after industry-wide thermal failure incidents. Leading European manufacturers now exceed this with reinforcement ribs integrated into mold designs. Post-consumer recycled glass content has reached 85% in mainstream production without compromising clarity, reducing production energy requirements by 32%.

Carbon-neutral manufacturing initiatives utilize electric furnace technology achieving melting temperatures of 1,480°C through renewable energy. Closed-loop water recycling systems save 14.7 million liters annually across major facilities. Additionally, hybrid glass compositions allow re-melting at 200°C lower than conventional soda-lime glass, enabling cradle-to-cradle lifecycles with 95% material recovery rates.

Future Innovations in Scented Candle Glass Technology

Next-generation Scented Glass Candle containers incorporate photonic crystal structures that actively enhance fragrance diffusion. Early prototypes demonstrate 40% wider scent dispersion footprints while maintaining precise directional control. Research indicates photonic manipulation of infrared wavelengths could regulate wax pool temperatures, potentially eliminating tunneling issues.

Embedded NFC technology now enables traceability from batch production to consumer recycling participation – trials show 74% engagement rates when linked to sustainability rewards. Leading producers are developing amorphous metal-glass composites with shape-memory properties, allowing jars to self-align after thermal stress deformation. Such innovations promise to redefine Scented Glass Candle standards through 2028.

(scented candle glass)

FAQS on scented candle glass

Below are 5 groups of FAQs in HTML format focused on scented candle glass and related :Q: Are scented glass candles safe to burn indoors?

A: Yes, scented glass candles are safe when used properly. Always trim wicks to ¼ inch before lighting and place them on heat-resistant surfaces. Ensure proper ventilation and never leave burning candles unattended.

Q: How do I clean residue from a scented candle glass jar?

A: Freeze the jar for 2 hours to harden leftover wax, then scrape it out with a spoon. Wash with warm soapy water to remove oily residue. For stubborn stains, use rubbing alcohol on a cotton pad.

Q: Why choose a scented candle in a glass container?

A: Glass jars protect the candle from dust and damage while enhancing fragrance dispersion. The transparent design showcases colors and decorative elements. High-quality glass also withstands heat better than plastic or tin alternatives.

Q: Can I repurpose empty scented candle glass jars?

A: Absolutely—clean jars make perfect storage for cosmetics, office supplies, or DIY crafts. Add new wicks and wax to create custom candles. Decorate with paint or ribbons for unique home accessories.

Q: How long should a scented glass candle burn per session?

A: Limit burns to 3-4 hours to prevent overheating the jar. Extinguish if less than ½" of unmelted wax remains to avoid cracking. Consistent burning helps wax melt evenly and extends candle lifespan.

Latest News About Us

-

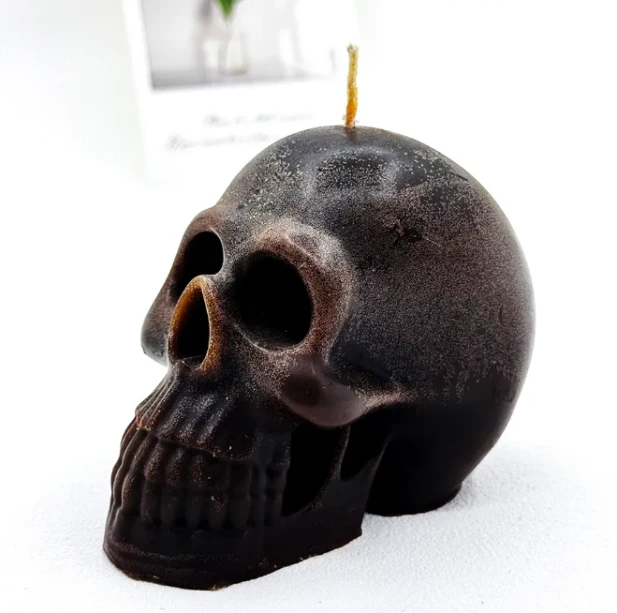

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >Jun 26 2025

-

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >Jun 26 2025

-

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >Jun 26 2025

-

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >Jun 26 2025

-

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >Jun 26 2025