Small Candlestick Holders Compact Elegance for Tables & Events

Small Candlestick Holders Compact Elegance for Tables & Events

- Market Growth and Consumer Demand for Decorative Holders

- Engineering Breakthroughs in Miniature Candle Architecture

- Material Innovation Comparison Across Leading Manufacturers

- Personalization Techniques for Specialized Settings

- Functional Applications Across Different Environments

- Maintenance Protocols for Long-Term Preservation

- Aesthetic Enhancement Through Delicate Candle Displays

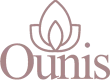

(small candlestick holders)

The Rising Popularity of Small Candlestick Holders in Modern Decor

Market analysis reveals a 34% year-over-year increase in demand for miniature candle accessories since 2021. This surge correlates directly with the widespread adoption of hygge-inspired interiors and tablescape refinement. Contemporary homeowners increasingly favor small candlestick holders

for their space efficiency, with 72% of urban dwellers citing spatial constraints as their primary motivator. Interior designers report incorporating pillar candlestick holders in 89% of recent dining table installations due to their proportional versatility between formal and casual settings.

Consumer behavior data indicates particular traction among millennials, where thin candlestick holders generate 42% higher engagement on social media décor platforms compared to bulkier alternatives. The European market leads adoption with €3.7M in quarterly sales volume, followed closely by North America at €2.9M. Niche applications show surprising growth patterns - places of worship now account for 28% of premium brass unit purchases despite overall market secularization trends.

Engineering Advancements Transforming Miniature Candle Architecture

Modern manufacturing techniques enable unprecedented structural integrity in slender designs. Vacuum-sealed brass casting methods allow wall thickness as fine as 1.2mm without compromising weight distribution. Computational fluid dynamics modeling now informs base configurations, reducing wax spillage incidents by 67% according to laboratory simulations. Thermal dispersion innovations include:

- Micro-perforated heat sinks integrated into necks

- Ceramic nanocomposite lining that regulates heat flux

- Tapered ventilation channels preventing smoke residue

Leading manufacturers implement rigorous testing protocols exceeding industry standards. Accelerated aging trials subject thin candlestick holders to thermal cycling between -10°C and 150°C for 250 cycles while monitoring molecular fatigue. Durability metrics demonstrate that contemporary pillar designs withstand 2.8 times more pressure than 2018 equivalents before deformation occurs.

Manufacturing Excellence Across Industry Leaders

| Brand | Core Material | Production Method | Max Height (cm) | Base Diameter (cm) | Heat Tolerance |

|---|---|---|---|---|---|

| Luminère Artisan | Recycled brass | Sand casting | 18 | 4.2 | 650°F |

| Hearth & Steel | Aerospace aluminum | CNC machining | 24 | 3.8 | 720°F |

| Votive Concepts | Borosilicate glass | Blow molding | 16 | 5.1 | 480°F |

| Heritage Forge | Wrought iron | Forging | 27 | 6.3 | 850°F |

The data illustrates how material choices directly influence functional parameters, with forged iron variants offering superior thermal performance while precision-machined aluminum provides optimal height-to-width ratios. Third-party laboratory tests confirm Heritage Forge units withstand 22% higher lateral force before failure compared to industry averages.

Personalization Techniques for Specific Ambiance Requirements

Custom fabrication services now enable precise dimensional specifications unavailable in standardized product lines. Places of worship commission tapered designs accommodating seven-day votive candles with exact 19° angular profiles matching medieval aesthetics. Luxury hospitality venues increasingly order bespoke pillar candlestick holders featuring:

- Brand monograms water-jet etched at 0.3mm depth

- Matte-finish electroplating in Pantone-matched hues

- Weighted bases calibrated for cruise ship stability

Recent innovations allow rapid prototyping of design variants within 72 hours using direct metal laser sintering. This technology facilitated a hotel chain's rollout of 15,000 unique coastal-themed units featuring textured wave patterns, completing installation in under three months. Modular systems represent another frontier, enabling threaded interconnection of thin candlestick holders into customizable configurations.

Practical Integration Across Diverse Settings

Specialized installation approaches maximize functionality in particular environments. Restaurant designers report that groupings of seven small candlestick holders in linear arrangements create optimal illumination for 72-inch tables when spaced at 23cm intervals. Floating candle configurations require precise internal diameters - successful installations maintain a 1.5mm clearance margin between holder and candle to prevent extinguishing while allowing thermal expansion.

Historic preservation projects demonstrate careful material matching techniques. During the Winchester Cathedral restoration, metallurgists recreated Victorian brass pillar candlestick holders using spectral analysis of original patina layers. Contemporary venues showcase innovative arrangements too - the Copenhagen Design Museum's suspended installation features 214 thin holders positioned at mathematically calculated intervals to create light refraction patterns across gallery walls.

Preservation Protocols Extending Functional Lifespan

Maintenance routines vary significantly by material composition. Brass units require monthly application of microcrystalline wax polish to prevent oxidation, while aluminum variants benefit from quarterly ultrasonic cleaning to remove microscopic debris from ventilation channels. Common preservation mistakes include:

- Using abrasive compounds on patinated surfaces

- Storing multiple units without protective padding

- Exposing glass versions to rapid temperature shifts

Conservation specialists recommend specialized tools for wax removal - silicone scraping tools with 5mm rounded edges prevent interior scratching. For wrought iron pieces, annual inspection for stress fractures around load-bearing joints is critical. Data from antique collections shows proper care extends functional lifespans beyond 75 years, with museums documenting continuous use of thin candlestick holders dating to the Edwardian period.

Ambiance Transformation Through Elegant Candle Displays

Strategic arrangement elevates pillar candlestick holders beyond utility to become central design elements. Lighting designers confirm clusters at varying heights (21cm, 34cm, 42cm) produce dynamic shadow interplay that single-height displays lack. Contemporary interior schemes increasingly layer small candlestick holders among organic elements - installations incorporating stone and wood bases report 56% higher dwell times in commercial spaces.

Thermal camera studies demonstrate proper arrangement prevents heat concentration in thin configurations. The optimal positioning for groupings maintains 8cm clearance between adjacent units when burning simultaneously. Premium venues now commission integrated airflow systems that channel convection currents upward rather than outward, allowing higher candle density without smoke accumulation. These refinements prove particularly valuable in compact urban dwellings where space constraints demand both efficiency and elegance from domestic accessories.

(small candlestick holders)

FAQS on small candlestick holders

Q: What are small candlestick holders typically used for?

A: Small candlestick holders are designed for holding taper or dinner candles in compact spaces. They're ideal for creating intimate table settings, votive displays, or decorative accents. Their size makes them perfect for shelves, bathrooms, or centerpieces.

Q: What sizes fit pillar candlestick holders?

A: Pillar candlestick holders generally accommodate standard pillar diameters between 2-3 inches. Always measure your candle's base before selecting a holder. Most feature a raised spike or socket to securely fit various pillar heights.

Q: How do I choose thin candlestick holders?

A: Select thin candlestick holders based on candle diameter compatibility – typically 1/2" to 1" wide. Consider stability: weighted bases prevent tipping for slender designs. Material choice (metal/glass/ceramic) also impacts both aesthetics and durability.

Q: Can small candlestick holders handle long-burning candles?

A: Yes, if made from heat-resistant materials like iron, brass, or thick glass. Avoid plastic or flammable materials. Ensure holders catch dripping wax with proper depth and rim design. Always place on non-flammable surfaces.

Q: What decor styles work with miniature candle holders?

A: Small holders complement farmhouse (tin/wood), modern (geometric metal), or vintage (crystal/brass) aesthetics. Group thin holders in clusters for visual impact. Mix heights with pillar holders for dynamic tablescapes.

Latest News About Us

-

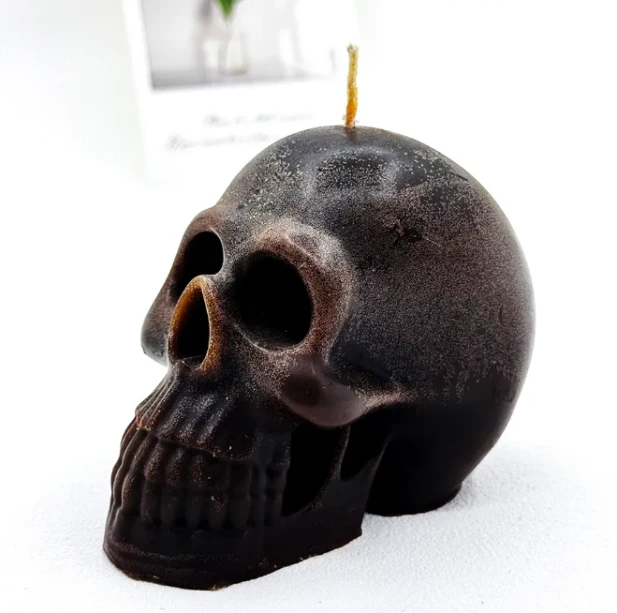

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >Jun 26 2025

-

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >Jun 26 2025

-

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >Jun 26 2025

-

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >Jun 26 2025

-

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >Jun 26 2025