Wholesale Glass Candle Holders | Bulk & Clear Votive Options

Wholesale Glass Candle Holders | Bulk & Clear Votive Options

Navigating the Market: Industry Trends in Glass Candle Holders

The market for glass candle holder wholesale continues to evolve, driven by shifting consumer preferences and industry demands. Current trends highlight a strong demand for minimalist designs, sustainable materials, and versatile applications. There's a notable increase in the adoption of durable, high-clarity glass, specifically engineered for repeated use in commercial settings such as hospitality, event management, and upscale retail. This shift underscores a move away from single-use plastics towards more enduring and aesthetically pleasing solutions. Furthermore, the emphasis on customization, allowing businesses to tailor designs to their specific brand identity, is becoming a key differentiator. Buyers are increasingly seeking suppliers who can offer diverse designs, ranging from sleek modern aesthetics to classic, ornate styles, ensuring broad appeal across various decorative themes.

Technological advancements in glass manufacturing have also enabled greater precision and cost-efficiency in producing glass candle holder bulk orders. This includes improved quality control mechanisms that ensure uniformity and reduce defects, critical for large-scale distribution. The global market for glass products, including glassware for home decor, is projected to grow, with a significant segment dedicated to decorative items like candle holders. This growth is fueled by an expanding middle class and an increased focus on ambiance in both commercial and residential spaces. Understanding these macro and micro trends is crucial for businesses aiming to optimize their procurement strategies and offer compelling products to their end-users.

The Manufacturing Precision: Crafting Quality Glass Candle Holders

Producing high-quality glass candle holder wholesale involves a sophisticated series of processes ensuring both aesthetic appeal and structural integrity. The primary material used is typically soda-lime glass, known for its clarity, versatility, and cost-effectiveness. For specialized applications requiring higher thermal resistance, borosilicate glass may be employed. The manufacturing process generally begins with melting raw materials—silica sand, soda ash, and limestone—in a furnace at extremely high temperatures, often exceeding 1700°C. This molten glass, or "gob," is then precisely fed into various forming operations.

Common manufacturing techniques include glass pressing, where molten glass is pressed into a mold by a metal plunger to create uniform shapes, ideal for votives and taper holders; glass blowing, for creating hollow items with intricate shapes; and centrifugal casting, where glass is spun in a rotating mold to form symmetrical items. Following the initial forming, the glass undergoes an annealing process, where it is slowly cooled in a controlled environment called a lehr. This critical step relieves internal stresses, preventing cracking and enhancing durability, thereby significantly extending the product's service life. Without proper annealing, the glass would be brittle and prone to fracture.

Common manufacturing techniques include glass pressing, where molten glass is pressed into a mold by a metal plunger to create uniform shapes, ideal for votives and taper holders; glass blowing, for creating hollow items with intricate shapes; and centrifugal casting, where glass is spun in a rotating mold to form symmetrical items. Following the initial forming, the glass undergoes an annealing process, where it is slowly cooled in a controlled environment called a lehr. This critical step relieves internal stresses, preventing cracking and enhancing durability, thereby significantly extending the product's service life. Without proper annealing, the glass would be brittle and prone to fracture.

Post-annealing, products proceed to finishing stages, including grinding, polishing, and cutting to achieve desired edges and surfaces. For instance, the Glass Taper Candle Holders often undergo precision cutting for their elegant facets. Quality control is rigorous, adhering to international standards such as ISO 9001 for quality management systems and often incorporating material safety standards like FDA compliance for lead-free glass. Each batch is inspected for clarity, dimensional accuracy, thermal shock resistance, and absence of defects like bubbles or inclusions. This stringent inspection ensures that every glass candle holder meets stringent industry specifications, making them suitable for demanding environments like luxury hotels and high-volume event planning.

Technical Specifications and Performance Metrics

When sourcing glass candle holder wholesale, understanding key technical parameters is essential for B2B buyers. These specifications directly impact product performance, durability, and suitability for various applications. For instance, the specific gravity of glass (typically 2.4-2.8 g/cm³) ensures appropriate weight and stability, crucial for preventing accidental tip-overs. Thermal shock resistance is another vital metric, particularly for items that will frequently experience temperature fluctuations from candle flames. High-quality glass can withstand rapid temperature changes without cracking, often tested to endure a differential of 80-100°C.

Optical clarity, measured by light transmittance (ideally >90% for clear glass), ensures a brilliant display of candlelight, which is paramount for aesthetic value. Surface hardness, typically 6-7 on the Mohs scale, contributes to scratch resistance and overall longevity in commercial use. Dimensional tolerances are meticulously controlled, often within ±0.5 mm, ensuring uniformity across large glass candle holder bulk orders. The expected service life for a well-maintained glass candle holder, depending on usage frequency and environment, can range from several years to a decade, making them a sustainable investment. Below is a comparative table of typical specifications:

| Parameter | Value Range | Relevance to Use |

|---|---|---|

| Material Type | Soda-Lime Glass / Borosilicate Glass | Durability, clarity, thermal properties |

| Thermal Shock Resistance | 80-100°C Delta T | Prevents cracking from heat changes |

| Light Transmittance | > 90% (Clear Glass) | Brilliance of candlelight, aesthetic appeal |

| Specific Gravity | 2.4 - 2.8 g/cm³ | Stability and weight |

| Surface Hardness (Mohs) | 6 - 7 | Scratch resistance, longevity |

| Dimensional Tolerance | ± 0.5 mm | Uniformity in bulk orders |

| Lead & Cadmium Content | Below Detection Limits (FDA/REACH Compliant) | Safety, environmental compliance |

Applications and Strategic Advantages

The versatility of glass candle holder wholesale extends across numerous sectors, making them an indispensable element for enhancing ambiance and decor. In the hospitality industry, particularly hotels and fine dining restaurants, they are central to creating a welcoming and luxurious atmosphere. Their ability to beautifully diffuse light adds warmth and sophistication to dining tables, lobbies, and guest rooms. Event planning companies heavily rely on `clear votive candle holders` and other glass variants for weddings, corporate galas, and festive celebrations, where they serve as elegant centerpieces or accent lighting. The durable nature of high-quality glass ensures repeated use, offering significant cost savings over time for these high-volume users.

Beyond hospitality, interior designers integrate glass candle holder for sale into residential and commercial projects to elevate spaces with timeless elegance. Retail businesses, from home decor boutiques to gift shops, find strong consumer demand for these products, recognizing their universal appeal and broad application. The inherent advantages of glass – its non-porous nature for easy cleaning, resistance to heat for safety, and environmental friendliness due to recyclability – make it superior to many alternative materials. Investing in premium glass candle holder bulk options ensures longevity, reduces replacement costs, and upholds the aesthetic integrity of any establishment sourcing glass candle holder wholesale solutions.

Beyond hospitality, interior designers integrate glass candle holder for sale into residential and commercial projects to elevate spaces with timeless elegance. Retail businesses, from home decor boutiques to gift shops, find strong consumer demand for these products, recognizing their universal appeal and broad application. The inherent advantages of glass – its non-porous nature for easy cleaning, resistance to heat for safety, and environmental friendliness due to recyclability – make it superior to many alternative materials. Investing in premium glass candle holder bulk options ensures longevity, reduces replacement costs, and upholds the aesthetic integrity of any establishment sourcing glass candle holder wholesale solutions.

Tailored Solutions: Customization and Partnership

For businesses seeking a unique brand identity, customization options for glass candle holder wholesale are paramount. Leading manufacturers offer extensive bespoke solutions, including custom sizing, unique shapes, and decorative finishes such as frosting, etching, or color tinting. This allows enterprises to create exclusive product lines that perfectly align with their brand aesthetics and target market. For instance, a luxury hotel chain might require taper candle holders with a specific logo etched onto the base, or a wedding planner might desire a unique geometric shape for a themed event.

Effective partnerships with manufacturers are built on a foundation of mutual understanding and reliable support. A reputable supplier of glass candle holder bulk products will provide comprehensive technical consultations, assist with design iterations, and offer samples for approval before large-scale production. This collaborative approach ensures that the final product not only meets but exceeds client expectations, adhering to precise specifications and quality benchmarks. Our commitment extends to delivering solutions that enhance operational efficiency and aesthetic appeal for our B2B partners, cementing long-term relationships built on trust and shared success.

Case Study & Trustworthiness: Our Commitment to Excellence

Our expertise in providing glass candle holder wholesale solutions is exemplified through successful collaborations. For over 15 years, we have partnered with leading hospitality groups and event management firms, delivering bespoke glassware that elevates their service offerings. For example, a major hotel chain recently procured over 5,000 units of our Glass Taper Candle Holders for their banquet halls, citing our superior product clarity, thermal resistance, and consistent delivery as key factors in their decision. The meticulous attention to detail in our manufacturing process, coupled with adherence to ISO 9001 quality management standards, ensures every product shipped meets the highest global benchmarks.

We maintain stringent quality assurance protocols at every stage, from raw material inspection to final packaging, guaranteeing product integrity and customer satisfaction. Our commitment to transparent communication and robust customer support underscores our trustworthiness. We offer detailed delivery timelines, typically ranging from 4-6 weeks for custom bulk orders depending on complexity and volume, and a comprehensive 1-year warranty against manufacturing defects. Our dedicated support team is available to address any inquiries, ensuring a seamless experience from initial consultation to post-delivery assistance for every clear votive candle holders order and beyond.

We maintain stringent quality assurance protocols at every stage, from raw material inspection to final packaging, guaranteeing product integrity and customer satisfaction. Our commitment to transparent communication and robust customer support underscores our trustworthiness. We offer detailed delivery timelines, typically ranging from 4-6 weeks for custom bulk orders depending on complexity and volume, and a comprehensive 1-year warranty against manufacturing defects. Our dedicated support team is available to address any inquiries, ensuring a seamless experience from initial consultation to post-delivery assistance for every clear votive candle holders order and beyond.

Frequently Asked Questions (FAQ)

-

Q: What materials are your glass candle holders made from?

A: Our candle holders are primarily crafted from high-quality soda-lime glass, with options for borosilicate glass for enhanced thermal resistance on specific products. All materials comply with relevant safety standards, including being lead and cadmium-free.

-

Q: Can we request custom designs or branding for large orders?

A: Absolutely. We specialize in custom solutions for glass candle holder bulk orders, including bespoke shapes, sizes, colors, and etching for logos or specific designs. Our design team works closely with clients to bring their vision to life.

-

Q: What is the typical lead time for a wholesale order?

A: Standard wholesale orders typically have a lead time of 4-6 weeks from order confirmation to dispatch, depending on order volume and customization requirements. Expedited options may be available upon request.

-

Q: Do you provide a warranty for your products?

A: Yes, we offer a 1-year limited warranty against manufacturing defects. Our commitment is to ensure the highest quality and durability of our glass candle holder for sale products.

Authoritative References

- ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

- ASTM International Standards on Glass and Glass Products. ASTM Committee C14.

- FDA Regulations for Glassware and Ceramicware. U.S. Food and Drug Administration.

- Journal of the American Ceramic Society, various articles on glass manufacturing and properties.

Latest News About Us

-

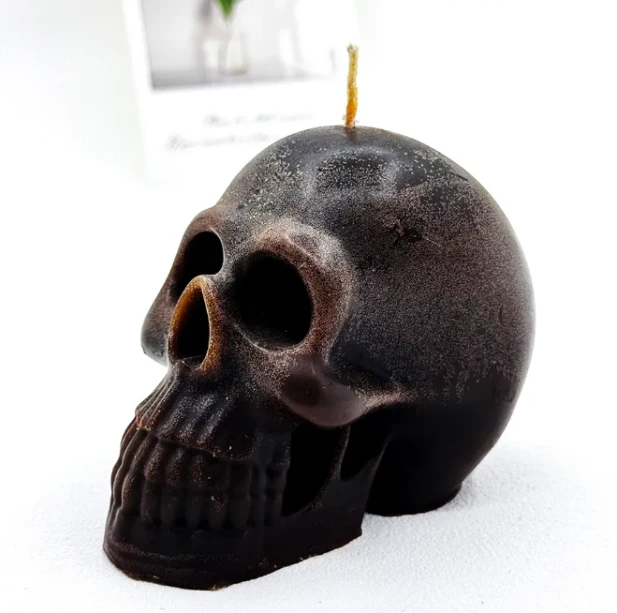

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >Jun 26 2025

-

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >Jun 26 2025

-

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >Jun 26 2025

-

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >Jun 26 2025

-

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >Jun 26 2025