Types of Candle Shapes Molding Techniques for Different Candle Shapes

Types of Candle Shapes Molding Techniques for Different Candle Shapes

The art of candle making has evolved dramatically, with innovative molding techniques creating endless possibilities for types of candle shapes. At Ounis Candle Company, we specialize in crafting shape candles that push creative boundaries while maintaining excellent burning performance. Our collection of cool shaped candles combines artistic design with technical precision to produce stunning decorative pieces that also function as high-quality candles. With over a decade of experience in candle manufacturing, we've perfected molding techniques that balance aesthetic appeal with practical functionality.

Traditional Molding Methods for Types of Candle Shapes

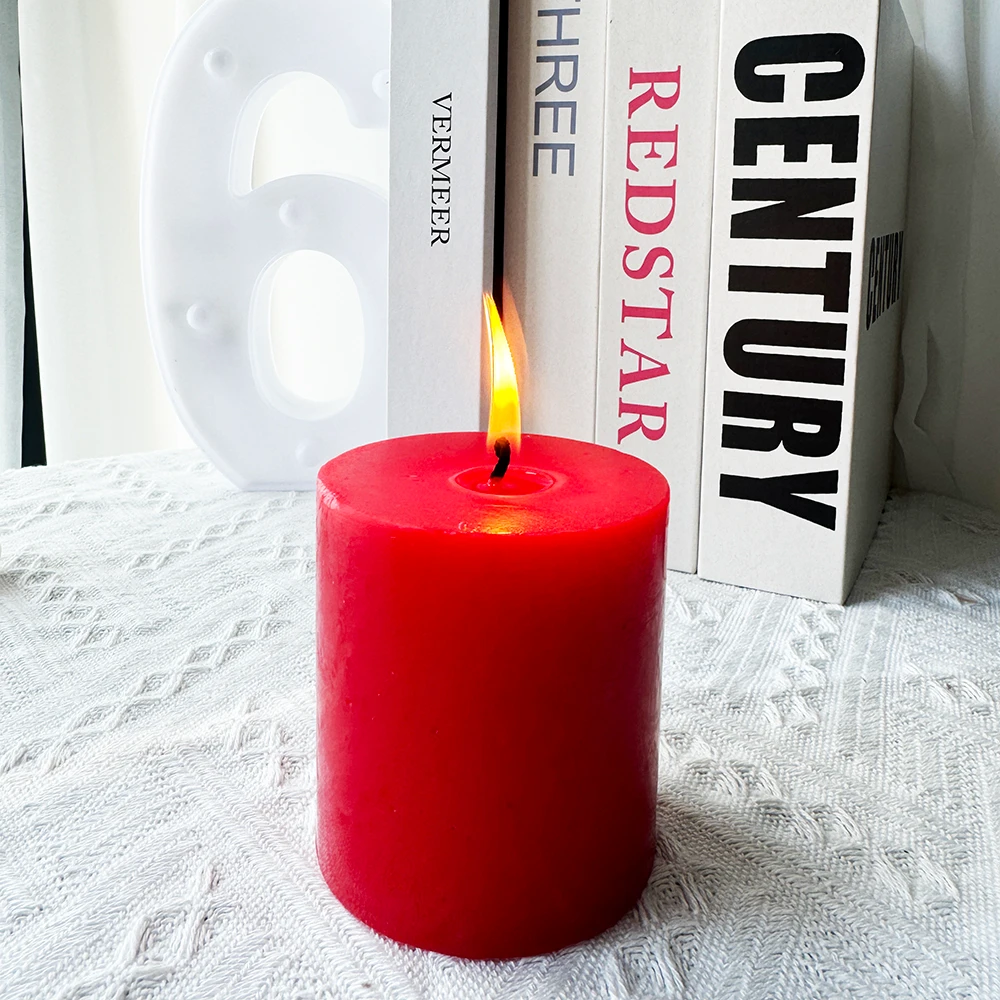

- Our aluminum molds for classic types of candle shapes (pillars, votives, tapers) feature precision-machined cavities that ensure consistent wall thickness between 5-7mm for optimal burn performance. These molds are temperature-controlled to maintain wax at 70-75°C during pouring.

• The shape candles production line uses CNC-milled steel molds with mirror-polished surfaces that achieve flawless finishes on geometric designs and architectural-inspired candles.

• For our cool shaped candles collection, we employ centrifugal casting techniques that distribute wax at precisely 120 RPM to fill complex molds with undercuts and fine details like facial features or intricate patterns.

• Our traditional mold workshop maintains over 500 standard types of candle shapes molds, with capacity to produce 20,000 units daily while maintaining ±1% dimensional consistency.

• The curing process for shape candles involves gradual temperature reduction from 65°C to 25°C over 8 hours to prevent stress fractures in detailed designs.

Silicone Molding Technology for Shape Candles

- Our food-grade platinum silicone molds with 30-40 Shore A hardness allow creation of shape candleswith ultra-fine details down to 0.2mm resolution, perfect for botanical and animal designs.

• The cool shaped candlesbenefit from flexible silicone molds that can stretch up to 400% for easy release of complex shapes like intertwined figures or delicate floral arrangements.

• Custom types of candle shapes in silicone molds undergo vacuum degassing at -29 Hg to eliminate air bubbles that could compromise surface details.

• Our proprietary silicone blend withstands 500+ pours at 85°C without degradation, ensuring consistent quality throughout production runs of shape candles.

• The cool shaped candles silicone molding department features 3D-printed prototypes that allow clients to approve designs before full mold production begins.

Injection Molding for Cool Shaped Candles

- Our 250-ton injection molding presses produce cool shaped candlesat cycle times of 45-60 seconds with 0.02mm dimensional tolerance for mass production.

• The shape candlesinjection process uses precision nozzles that maintain wax at 80±2°C with flow rates optimized for each types of candle shapes design.

• Multi-material injection allows production of cool shaped candles with contrasting colors and embedded decorative elements in a single operation.

• Automated robotic arms remove shape candles from molds and place them on cooling conveyors that maintain 22°C ambient temperature for perfect setting.

• Our injection molding quality control includes laser measurement of every 50th cool shaped candle to verify critical dimensions remain within specification.

Hand-Poured Techniques for Artisan Shape Candles

- Master artisans layer colored waxes at precisely 65°C to create unique shape candleswith organic, flowing patterns that machines cannot replicate.

• Our signature cool shaped candlescollection features hand-poured designs where each piece shows subtle variations in color distribution and texture.

• The types of candle shapes produced through hand-pouring include our marbled designs (created by swirling 3-5 colors), ombre effects (with 7-9 color gradients), and watercolor-style candles.

• Small-batch shape candles undergo 48-hour curing in climate-controlled rooms (22°C, 45% RH) to ensure perfect crystallization and fragrance retention.

• Each hand-poured cool shaped candle receives individual inspection and burn testing before being approved for sale.

Innovative Materials for Types of Candle Shapes

- Our proprietary wax blend for shape candlescombines paraffin, soy, and microcrystalline waxes in ratios optimized for different types of candle shapes.

• The cool shaped candlesline includes transparent gel wax with refractive indexes matched to embedded decorative elements for optimal visual impact.

• Rubberized wax compounds in our shape candles provide 150% elongation capacity for flexible designs that won't crack in shipping or storage.

• UV-stabilized pigments in our cool shaped candles maintain vibrant colors for 5+ years even with indirect sunlight exposure.

• The wicks in our types of candle shapes are specially selected based on each design's diameter and wax composition to ensure clean, even burns.

Types of Candle Shapes FAQs

Q: How does wax type affect the production of different types of candle shapes?

A: Wax type significantly impacts types of candle shapes production. Soy wax’s lower melting point allows intricate molds for detailed shapes, while paraffin’s rigidity suits tall pillar shapes. Beeswax’s natural texture works best for hand-rolled shapes, and palm wax’s opacity is ideal for layered or marbled designs. Manufacturers adjust melting temperatures and pouring techniques based on wax characteristics to ensure shape consistency.

Q: What challenges do manufacturers face when producing shape candles with complex designs?

A: Producing shape candles with complex designs requires precise mold engineering. Issues like air bubbles in detailed molds, uneven cooling in asymmetrical shapes, or wick misalignment in tall structures are common. Manufacturers use vacuum molding for air-free pours, multi-zone cooling systems, and custom wick holders to maintain structural integrity during production.

Q: How do manufacturers ensure safety in cool shaped candles with unique structures?

A: Safety in cool shaped candles starts with material selection—non-toxic waxes and lead-free wicks are mandatory. For unconventional shapes (e.g., hanging or multi-wick designs), manufacturers test burn stability to prevent tipping or uneven melting. They also ensure wick size matches wax volume to avoid overheating, and label designs with specific burn time recommendations.

Q: Can automated systems handle the production of diverse types of candle shapes?

A: Automated systems excel in mass-producing standard types of candle shapes like cylinders or tapers, using conveyor belts and pre-programmed molds. However, intricate or irregular shapes often require manual intervention. Manufacturers blend automation (for pouring and basic molding) with hand-finishing (for details like sculpting or adding decorative elements) to balance efficiency and design complexity.

Q: How does production scaling work for bulk orders of cool shaped candles?

A: Scaling cool shaped candles for bulk orders involves pre-producing molds in quantity and streamlining material flow. Manufacturers group similar shapes to optimize machine setups, use bulk wax melting tanks for consistency, and implement batch quality checks (e.g., burn tests on every 100th unit). This approach maintains design integrity while reducing per-unit production time for large orders.

Welcome to Ounis (Shijiazhuang) Import&Export Co., Ltd., your premier one-stop solution for candles and candle accessories. With over a decade of export expertise in Shijiazhuang, Hebei, our professional team delivers global quality in Scented Candles, Pillar Candles, Beeswax Candles, LED Candles, and more.

Crafted with premium essential oils and sustainable waxes, our scented candles blend Indonesian patchouli, French lavender, and citrus notes for evolving aromatic experiences. Explore elegant pillar candles, festive birthday designs, and safe LED flameless options. Complement your space with our glass/metal holders or wax warmers, designed for both aesthetics and functionality.

Exported to America, Europe, Australia, and South Asia, our ODM/OEM services offer custom shapes, fragrances, and packaging. Upholding "Integrity-based, Win-Win Cooperation", we ensure strict quality control and personalized service. Join us to light up homes worldwide—your trusted partner in candle craftsmanship.

Visit us for timeless warmth and innovation: https://www.ouniscandle.com/

Последние новости о нас

-

The Warm Glow of Everyday Comfort: Inside the World of Candle MakingWhen was the last time you truly relaxed? Maybe it was while watching the flame of a soft candle flicker gently in a quiet room, or catching a calming lavender scent waft through your home after a long day.Read More >

The Warm Glow of Everyday Comfort: Inside the World of Candle MakingWhen was the last time you truly relaxed? Maybe it was while watching the flame of a soft candle flicker gently in a quiet room, or catching a calming lavender scent waft through your home after a long day.Read More >Aug 21 2025

-

Scented Serenity: Elevate Ambience With Glass CandlesIn the world of home decor and personal wellness, the allure of a scented glass candle lies in its ability to combine visual elegance with fragrant comfort.Read More >

Scented Serenity: Elevate Ambience With Glass CandlesIn the world of home decor and personal wellness, the allure of a scented glass candle lies in its ability to combine visual elegance with fragrant comfort.Read More >Aug 21 2025

-

Lighting The Future: Bulk Flameless Candles for Elegant AmbienceIn a world increasingly conscious of both safety and sustainability, flameless candles have emerged as the elegant, smoke-free solution for modern ambiance.Read More >

Lighting The Future: Bulk Flameless Candles for Elegant AmbienceIn a world increasingly conscious of both safety and sustainability, flameless candles have emerged as the elegant, smoke-free solution for modern ambiance.Read More >Aug 21 2025

-

Candle Holder Mirror Plate For Elegant Decor AccentsWhen you’re designing a tablescape that demands elegance, adding a candle holder mirror plate instantly enhances the entire visual impact.Read More >

Candle Holder Mirror Plate For Elegant Decor AccentsWhen you’re designing a tablescape that demands elegance, adding a candle holder mirror plate instantly enhances the entire visual impact.Read More >Aug 21 2025

-

Elegant 3 Piece Candle Holders for Every HomeLooking for a touch of luxury to elevate your space without breaking the bank? A 3 piece crystal candle holder set is more than just a decorative piece—it's an expression of elegance.Read More >

Elegant 3 Piece Candle Holders for Every HomeLooking for a touch of luxury to elevate your space without breaking the bank? A 3 piece crystal candle holder set is more than just a decorative piece—it's an expression of elegance.Read More >Aug 21 2025