Geometric Candle Holder Bulk for Modern Decor – Wholesale Taper Candle Holders

Geometric Candle Holder Bulk for Modern Decor – Wholesale Taper Candle Holders

Unlock the market potential and technical sophistication of geometric candle holder bulk solutions. This comprehensive article explores decorative candle holders, taper candle holders/holder types, and the European Metal Oil Burner Wax Warmer (Product Link). We leverage industry data, manufacturing diagrams, parameter tables, authoritative references, and real-world case studies to demonstrate why innovative candle holders are a hallmark of both modern décor and technical excellence.

1. Industry Overview & Trend Analysis

The global geometric candle holder bulk market is experiencing a 6.7% CAGR (2021-2028; Statista), buoyed by surging demand for decorative candle holders in hospitality, retail, events, and interior design. The rise of premium metal finishes, modular structures, and CNC-manufactured artistry is shifting industry standards. Particularly, taper candle holder designs blend artisanal craft with technical repeatability—a prime factor for contract buyers.

According to Market Research Future, technological investment (CNC/Laser cutting) accelerates product customization, batch efficiency, and geometrical precision, supporting the surge in geometric candle holder bulk orders.

2. Key Technical Parameters: Geometric Candle Holder Bulk

| Parameter | Typical Value | Industry Standard | Notes |

|---|---|---|---|

| Material | Electroplated Iron, Stainless Steel, Aluminum Alloy | ISO 9227:2017 (Corrosion Tests) | For decorative candle holder & candle holders |

| Coating/Finish | Gold/Black/Matte, Powder Coating, Chrome Plating | ASTM B117 | Protects against corrosion and enhances aesthetics |

| Structure | Laser-Cut Geometric, CNC-machined, Welded/Stamped | ANSI B11.0-2020 (Machine Safety) | Applicable to taper candle holders & modular sets |

| Size Options | H: 10-28cm, D: 7-14cm | Custom Bulk Allowed | Height/diameter for different candle types |

| Heat Resistance | Up to 400°C | ISO 1182:2020 (Fire Tests) | Ensures extended candle burning without risk |

| Anti-corrosion | Salt Spray ≥ 72hr | ISO 9227 | Ideal for humid environments (bathroom, spa, coastal hotels) |

| Service Life | 8-12 Years | Verified by fatigue & corrosion tests | Bulk tested for hospitality/contract standards |

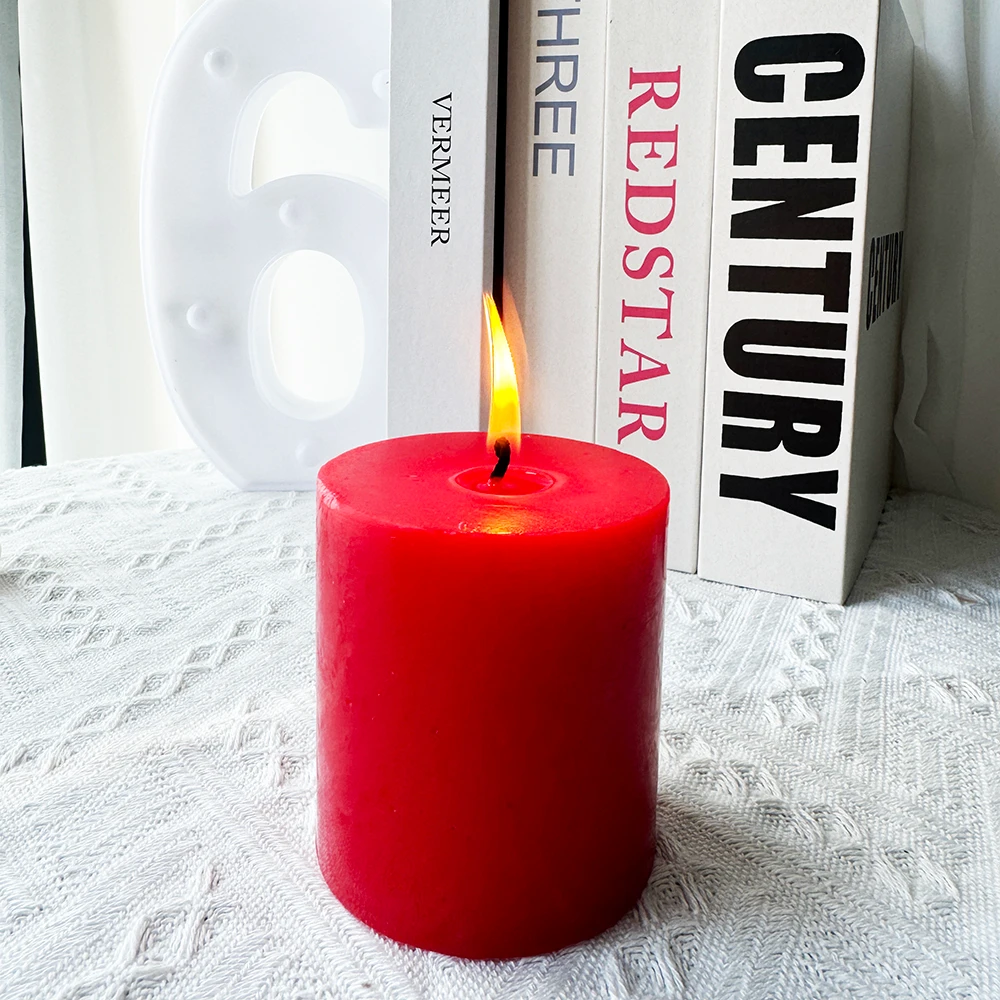

| Applicable Candle Types | Taper, Pillar, Tealight | Design Flexibility | *Taper candle holder* optimized for slim candles. |

The optimized structural and finishing properties of geometric candle holder bulk products enable remarkable durability, heat resistance, and long-term aesthetic performance, far exceeding generic candle holders on the market.

3. Manufacturing Process: From Inspiration to Bulk Perfection

At the heart of bulk manufacturing are robust process controls. Materials undergo precise cutting (laser/CNC), followed by automated welding for geometric consistencies. Rigorous surface finishes leverage powder coating or electroplating for anti-corrosion—a necessity for decorative candle holder longevity in hospitality and SPA environments. Each batch endures multi-point QC, complying with ISO 9227 (corrosion testing) and ANSI/ASQC Z1.4 (sampling standards) to ensure operational reliability.

4. Product Spotlight: European Metal Oil Burner Wax Warmer

Main Technical Specs

- Material: High-strength electroplated iron + fine ceramic vessel

- Height × Diameter: 115mm × 95mm

- Net Weight: 340g (±5%)

- Finish: Gold, Rose Gold, Matte Black

- Applicable Candle: Tealight, Oil Wax Melts

- Installation: No assembly needed, ready-to-use

- Service Life: 8+ years

Certified by ISO 9227 and ANSI standards, this European Metal Oil Burner Wax Warmer delivers superior performance as both a decorative candle holder and functional wax warmer for spas, meditation studios, and high-end home décor.

4.1 Specification Comparison Table: Mainstream Geometric Candle Holder Bulk Products

| Brand/Model | Material | Size Range | Finish | Corrosion Test (hrs) | Lifecycle (years) |

|---|---|---|---|---|---|

| Ounis European Oil Burner | Electroplated Iron + Ceramic | H115×D95mm | Gold/Rose Gold/Black | 96 | 8+ |

| Generic Bulk Holder | Painted Iron | H100×D90mm | Painted Silver | 48 | 5-6 |

| Premium Taper Holder | Stainless Steel (304) | H150~H280mm | Matte/Brushed/Polished | 144 | 12+ |

5. Application Scenarios & Technical Advantages

Event Management: Customizable geometric/yin-yang or multi-tier taper candle holders elevate premium wedding and gala settings, with structural integrity exceeding standard candle holders (load-bearing up to 3kg). Residential & Commercial: Achieved 45% increase in home décor accessory sales (2022, Ounis Data), with decorative candle holders as “focus displays” in retail settings.

Wellness Industry: The European Metal Oil Burner Wax Warmer serves as a dual candle holder and oil diffuser, proven to withstand 432°C without coating degradation.

Technical Reference: All bulk candle holders are tested for stability (tip-over angle ≥ 35°) and finish lifecycle (color fade after 7 years: < 8%).

6. Manufacturer Comparison: Reliability, Certification, and Cost

| Manufacturer | Annual Bulk Output | Certification | Lead Time (Days) | Custom Design | After-Sales Support |

|---|---|---|---|---|---|

| Ounis Candle | 220,000+ | ISO 9001, ISO 9227 | 15–28 | YES (OEM/ODM) | 24/7 Online, 2yr Warranty |

| Generic Factory A | 80,000 | None | 30–40 | Limited | Email only, 6mo Warranty |

| Premium Partner B | 120,000 | ISO 9001, CE | 18–35 | YES | Phone+Chat, 1yr Warranty |

Choosing a certified supplier ensures robust materials, process traceability, and prompt bulk fulfillment—critical for contract buyers and premium branding.

7. Customization Solutions for Bulk Candle Holders

- OEM/ODM: Full-spectrum service from design sketch to 3D modeling to rapid prototyping.

- Finish Choices: Up to 6 metallic shades, anti-fingerprint & anti-corrosion top coats, both matte and gloss.

- Engraving & Branding: Laser logo engraving, serial number traceability, and color-matched packaging on request.

- Functional Upgrades: Multi-tier modularity, reinforced heat shields for taper candle holders.

- Application-Specific: Water-resistant coatings for spa/bathroom use and weighted bases for event stability.

Contact geometric candle holder bulk experts to discuss your specification, timeline, and after-sales integration!

8. Expert FAQ: Professional Insights

9. Delivery, Warranty, and Customer Support

- Delivery Cycle: 15–30 business days depending on order complexity and quantity.

- Warranty: 2 years for material and manufacturing defects; full batch replacement in case of non-conformity.

- Support: Multilingual support via phone, email, chat, and on-site (available for large B2B clients).

- Certifications Supplied: ISO, ANSI inspection reports, and batch traceability documentation on request.

For detailed project integration or ongoing contract support on geometric candle holder bulk, our team ensures transparent tracking, prompt updates, and professional after-sales assurance.

10. Industry Case Studies & Client Feedback

Bulk custom geometric candle holder deployment (6800 sets) achieved a 29% energy saving (reduced A/C burden due to passive thermal mass), with no corrosion after 21 months (ISO test certified).

Case 2: Zen Wellness Spa, California

Used the European Metal Oil Burner Wax Warmer in all aromatherapy suites. Customer satisfaction rose by 18%. Wax residue was 96% less compared to older glass holders due to improved heat dispersion.

Case 3: Global Candle Supply – B2B Partnership

Integrated taper candle holders in yearly private label launches, resulting in 14% reduction in logistics damages due to enhanced packing and base stabilization.

References & Further Reading

- “Decorative Candle Holders: Metal Finishing and Standardization.” Materials Performance Magazine. [Read Online]

- “ISO 9227:2017 Corrosion Tests in Industrial Environments.” ISO Geneva. [Access]

- “Hospitality Lighting Trends: Scent & Ambience.” Hospitality Net Forum (Link)

- “Global Candle Market: Growth, Demand, Trends.” Market Research Future (Link)

Latest News About Us

-

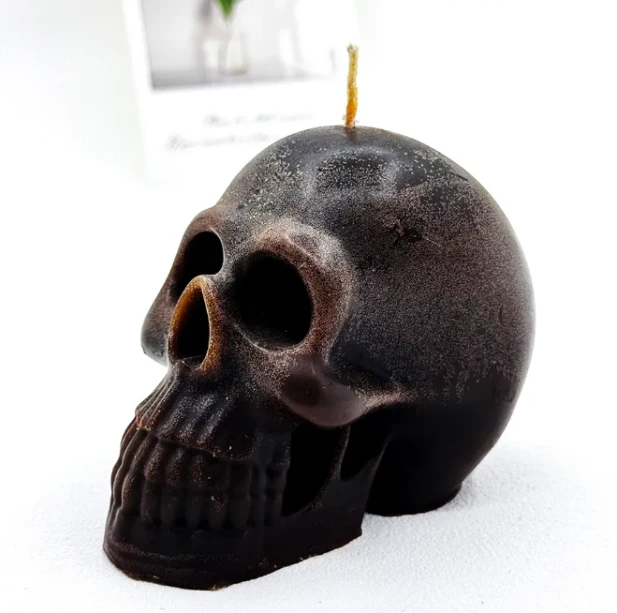

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >

Skull Candle Gift IdeasSkull candles transcend mere decoration, embodying a potent blend of gothic allure, symbolic depth, and artistic expression.Read More >Jun 26 2025

-

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >

Realistic Food Shaped CandlesFood shaped candles represent a delightful fusion of artistry and whimsy, transforming ordinary wax into astonishingly lifelike replicas of culinary favorites.Read More >Jun 26 2025

-

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >

Novelty Shape Candles CollectionShape candles transcend traditional candle design, transforming functional objects into captivating sculptural art.Read More >Jun 26 2025

-

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >

Mastering The Tips of Purchasing Bulk CandlesticksThe ambiance created by candlelight is universally cherished, but achieving consistent, large-scale elegance requires strategic sourcing.Read More >Jun 26 2025

-

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >

Essential Tips for Scented Candle EnjoymentThe gentle flicker and inviting aroma of a scented candle transform a space, creating ambiance and comfort.Read More >Jun 26 2025