Decoding the Evolving Landscape of Scented Candles for B2B Procurement

Decoding the Evolving Landscape of Scented Candles for B2B Procurement

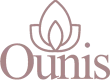

The global market for scented candles is experiencing robust growth, driven by increasing consumer demand for ambiance, wellness, and personalized home decor. For B2B stakeholders, understanding the nuances across various product categories—from compact small scented candles ideal for gift sets or intimate spaces, to lavish big scented candles designed for grand interiors and prolonged burn times—is critical. This sector is characterized by continuous innovation in wax formulations, fragrance profiles, and sustainable manufacturing practices. Notably, the demand for seasonal offerings like holiday scented candles sees significant spikes, requiring suppliers to maintain agile production lines and diversified product portfolios. Furthermore, the aesthetic appeal, which defines truly beautiful scented candles, plays an increasingly pivotal role in market differentiation, influencing brand perception and customer loyalty across hospitality, retail, and corporate gifting segments. Navigating these trends effectively enables businesses to capture emerging market opportunities and satisfy a diverse clientele.

Precision in Production: The Advanced Manufacturing of Scented Candles

The manufacturing of high-quality scented candles is a meticulous process, far removed from simple wax melting. It begins with the precise selection and blending of waxes, such as 100% natural soy wax (often preferred for its clean burn and renewable nature), paraffin wax for robust scent throw, or bespoke blends incorporating coconut or beeswax for enhanced performance. This foundational step dictates the candle's burn characteristics, scent throw, and overall lifespan. Following this, the carefully formulated fragrance oils, adhering to International Fragrance Association (IFRA) standards for safety and quality, are blended into the molten wax at specific temperatures to ensure optimal dispersion and retention.

Wick selection is equally critical, involving pre-waxed cotton or sustainably sourced wooden wicks, precisely sized according to the container's diameter and wax blend to ensure a full, even melt pool and prevent tunneling. Containers, often crafted from high-grade glass, ceramic, or metal, undergo stringent cleaning protocols. The pouring process itself is executed under controlled temperature and atmospheric conditions to prevent air bubbles and ensure a smooth, flawless surface finish. Post-pour, a crucial curing period allows the wax and fragrance to properly bind, maximizing scent throw during use. Each batch, whether it be a collection of small scented candles or an order of grand big scented candles, undergoes rigorous quality control checks, including burn tests for flame height, melt pool diameter, and soot production, alongside olfactory assessments for both cold and hot throw.

Manufacturing standards, often guided by industry best practices akin to ISO-level quality management, ensure consistency and safety. This includes adherence to ASTM F2417 for candle fire safety and various local regulations regarding material safety and labeling. The longevity and optimal performance of these products in diverse environments, from retail displays to luxury hotel rooms, are direct outcomes of these stringent manufacturing and testing protocols.

Technical Parameters and Performance Data

Understanding the technical specifications of scented candles is paramount for B2B buyers to make informed procurement decisions. Parameters like wax blend composition, fragrance oil concentration, wick type, and container dimensions directly influence performance metrics such as burn time, scent throw, and aesthetic appeal. The following table provides a comparative overview of typical parameters across different scented candle categories, highlighting the diversity and specialization within the market.

Scented Candle Category Parameter Comparison

|

Parameter |

Small Scented Candles |

Holiday Scented Candles |

Big Scented Candles |

Beautiful Scented Candles (Premium) |

|

Typical Weight (Net) |

60g - 120g (2-4 oz) |

150g - 250g (5-9 oz) |

400g - 1000g+ (14-35 oz+) |

200g - 600g (7-21 oz) |

|

Approx. Burn Time |

15 - 30 hours |

30 - 60 hours |

60 - 150+ hours |

40 - 100 hours |

|

Fragrance Load |

6% - 8% |

8% - 12% (often stronger) |

7% - 9% |

9% - 12% (complex blends) |

|

Scent Throw (Hot) |

Moderate (for small rooms) |

Strong (distinctive) |

Robust (for large areas) |

Excellent & Balanced |

|

Материал контейнера |

Glass, Metal Tins |

Decorated Glass, Ceramic |

Large Glass Jars, Ceramic Bowls |

Artisanal Glass, Porcelain, Stone |

Market Share of Wax Types in Scented Candles (Illustrative Pie Chart Data)

The choice of wax significantly impacts a candle's environmental footprint, burn performance, and cost. While paraffin remains dominant due to its cost-effectiveness and excellent scent throw, natural waxes are gaining substantial market share. An illustrative breakdown of wax market share typically shows:

- ‣Paraffin Wax: ~45%

- ‣Soy Wax: ~35%

- ‣Coconut Wax/Blends: ~10%

- ‣Beeswax/Other Natural Waxes: ~10%

This distribution reflects a growing consumer preference for sustainable and natural options, influencing procurement strategies for a wide range of products, including beautiful scented candles that prioritize both performance and eco-friendliness.

Application Scenarios and Technical Advantages

Scented candles serve a multitude of purposes across various industries, extending far beyond simple home decor. In the hospitality sector, from boutique hotels to luxury resorts, big scented candles are often deployed in lobbies and common areas to create a signature ambiance, enhancing brand identity and guest experience. Small scented candles, conversely, find their niche in individual guest rooms or as turndown service amenities, offering a personalized touch. Retail environments utilize strategic scenting to influence consumer behavior and improve the shopping experience, with fragrance profiles carefully chosen to align with brand ethos.

The technical advantages offered by professionally manufactured candles include consistent burn performance, minimal soot production, and optimal scent throw, ensuring a premium user experience. For instance, a well-wicked candle avoids tunneling, maximizing wax consumption and delivering fragrance evenly throughout its burn cycle. For seasonal campaigns, meticulously crafted holiday scented candles leverage specific fragrance notes like cinnamon, pine, or frankincense to evoke festive emotions, becoming highly sought-after during peak seasons. Furthermore, the aesthetic versatility of beautiful scented candles makes them ideal for corporate gifting, real estate staging, and event decor, where visual appeal is as crucial as olfactory impact. These products not only enhance sensory environments but also contribute to brand recall and perceived value, demonstrating a strong return on investment for businesses.

Customization Solutions for Diverse Business Needs

In a competitive market, customization offers a distinct advantage for B2B clients. Leading manufacturers provide extensive customization options for scented candles, allowing businesses to create unique product lines that perfectly align with their brand identity and target audience. This includes bespoke fragrance development, where expert perfumers collaborate with clients to craft signature scents that resonate with their brand values or specific campaign themes. Wax blends can be tailored to meet specific performance requirements, such as extended burn times for large-scale operations or an ultra-clean burn for enclosed spaces.

Container customization is another significant area, encompassing various materials, shapes, colors, and finishes—from minimalist clear glass for modern brands to ornate ceramic vessels for luxury segments. Branding elements such as custom labels, embossed lids, and specialized packaging further enhance product differentiation. For example, a luxury spa might require beautiful scented candles in custom-designed ceramic jars with a calming lavender and chamomile blend, while a corporate client might opt for small scented candles with their logo, packaged elegantly for an employee appreciation gift. Manufacturers capable of delivering comprehensive, end-to-end customization, from conceptualization to bulk production, are invaluable partners in achieving unique market positioning and fulfilling niche demands efficiently.

Illustrative Application Cases and Client Successes

Real-world applications demonstrate the tangible benefits of high-quality scented candles. A prominent luxury hotel chain, for example, partnered with a specialized manufacturer to develop a signature line of big scented candles and diffusers for their lobby and suite areas. This bespoke fragrance, diffused consistently, became a recognizable element of their brand experience, significantly enhancing guest satisfaction scores and leading to increased direct sales from their gift shop. The project involved careful testing to ensure optimal throw without being overpowering, alongside compliance with stringent safety standards for public spaces.

Another case involves a national retail chain launching its annual holiday scented candles collection. By collaborating on trend forecasting and custom fragrance development, they introduced a line of uniquely festive scents in attractive, holiday-themed packaging. This led to a 25% increase in seasonal candle sales compared to the previous year, highlighting the impact of timely, targeted product offerings. Even small businesses benefit: a subscription box service specializing in self-care items consistently sources unique small scented candles from a trusted vendor. The reliability in product quality and consistent delivery has been instrumental in maintaining their high subscriber retention rates and positive customer feedback, showcasing the importance of reliable supply chain partners. These examples underscore how strategic partnerships and high-quality scented candles can drive measurable business outcomes.

Professional Q&A: Deep Dive into Scented Candle Terminology

Q1: What is 'Fragrance Load' in scented candles?

A1: Fragrance load refers to the percentage of fragrance oil used in relation to the weight of the wax. A typical range for high-quality candles is 6-12%. A higher fragrance load doesn't always mean a stronger scent; it must be balanced with the wax type and wick to ensure efficient diffusion without impacting burn quality.

Q2: Explain 'Scent Throw' (Hot Throw vs. Cold Throw).

A2: Cold throw is the scent strength of the candle when it is unlit and at room temperature. Hot throw is the scent strength and diffusion when the candle is actively burning and the wax pool is fully melted. Both are crucial for determining a candle's overall fragrance performance, especially for products like holiday scented candles where immediate impact is desired.

Q3: What are the benefits of using natural waxes like Soy or Coconut wax?

A3: Natural waxes are renewable, biodegradable, and typically burn cleaner, producing less soot than traditional paraffin. Soy wax, for instance, has a lower melting point, leading to a slower, longer burn. Coconut wax is known for its excellent scent throw and creamy appearance, contributing to the appeal of beautiful scented candles.

Q4: What is 'Wick Centering' and why is it important?

A4: Wick centering refers to the precise placement of the wick in the exact center of the candle container. Proper centering ensures an even melt pool, preventing tunneling (where wax builds up around the edges) and maximizing the candle's burn time and scent throw. It's a critical aspect of manufacturing for all sizes, from small scented candles to the largest ones.

Q5: What are IFRA Standards?

A5: IFRA (International Fragrance Association) Standards are a set of safety guidelines for the use of fragrance ingredients, established to ensure the safe enjoyment of perfumes and perfumed products. Adherence to IFRA standards is a hallmark of reputable manufacturers, guaranteeing that fragrance oils used in products are safe for consumers and the environment.

Q6: How does container material affect candle performance?

A6: Container material influences heat dissipation, which in turn affects the melt pool and burn consistency. Materials like glass or ceramic retain heat well, aiding in a full melt pool. The container's shape and thickness also dictate wick size and overall burn performance. Aesthetically, the container is integral to the perception of beautiful scented candles.

Q7: What is 'Candle Curing' and why is it necessary?

A7: Candle curing is the period of time after a candle is poured during which the wax and fragrance oil bind together and solidify. This process, typically lasting 1-2 weeks, significantly improves the candle's scent throw and burn quality by allowing the fragrance molecules to fully integrate into the wax matrix. Skipping or rushing the curing process can result in a weaker scent.

Trustworthiness and Commitment

Our commitment to quality extends beyond product specifications. We prioritize transparent communication regarding production timelines, offering clear delivery schedules tailored to project scope and quantity, ensuring that your orders of small scented candles or custom big scented candles arrive when needed. All products are manufactured under rigorous quality control protocols and comply with international safety standards, backed by comprehensive testing data and certifications. We stand by our products with clear warranty policies and dedicated customer support, ensuring seamless post-purchase experience. Our long-standing industry relationships and a proven track record of successful client collaborations, from retail giants to specialized boutiques, underscore our reliability and expertise in delivering exceptional scented candle solutions that consistently exceed expectations.

References

- Consumer Product Safety Commission (CPSC) - Candle Fire Safety Information.

- International Fragrance Association (IFRA) - Standards and Guidelines for Fragrance Safety.

- National Candle Association (NCA) - Industry Standards and Best Practices.

- American Society for Testing and Materials (ASTM) - Standards for Candle Performance.

Последние новости о нас

-

Navigating the Scented Candle Market: Trends and Opportunities for B2B ProcurementThe global scented candle market is experiencing robust growth, driven by increasing consumer awareness of wellness, home aesthetics, and the desire for personalized sensory experiences.Read More >

Navigating the Scented Candle Market: Trends and Opportunities for B2B ProcurementThe global scented candle market is experiencing robust growth, driven by increasing consumer awareness of wellness, home aesthetics, and the desire for personalized sensory experiences.Read More >Aug 26 2025

-

Market Dynamics and Emerging Trends in Candle ManufacturingThe global candle market is experiencing dynamic shifts, driven by evolving consumer preferences and innovative manufacturing techniques.Read More >

Market Dynamics and Emerging Trends in Candle ManufacturingThe global candle market is experiencing dynamic shifts, driven by evolving consumer preferences and innovative manufacturing techniques.Read More >Aug 26 2025

-

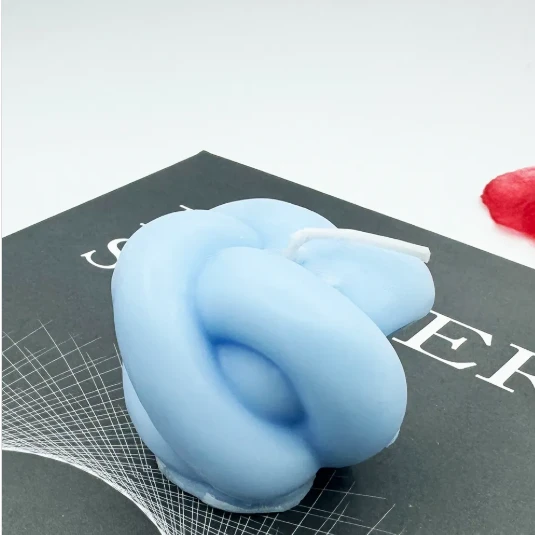

Introduction to Artisan Ball & Knot Candles: Market Dynamics and InnovationThe global home decor and luxury goods market continues to expand, driven by increasing consumer demand for unique, aesthetically pleasing, and sustainable products.Read More >

Introduction to Artisan Ball & Knot Candles: Market Dynamics and InnovationThe global home decor and luxury goods market continues to expand, driven by increasing consumer demand for unique, aesthetically pleasing, and sustainable products.Read More >Aug 26 2025

-

Exploring the Evolving Landscape of Art Shape CandlesThe market for decorative candles has witnessed a significant transformation, moving beyond traditional pillars and votives to embrace intricate and visually compelling designs.Read More >

Exploring the Evolving Landscape of Art Shape CandlesThe market for decorative candles has witnessed a significant transformation, moving beyond traditional pillars and votives to embrace intricate and visually compelling designs.Read More >Aug 26 2025