Exploring the Evolving Landscape of Art Shape Candles

Exploring the Evolving Landscape of Art Shape Candles

The market for decorative candles has witnessed a significant transformation, moving beyond traditional pillars and votives to embrace intricate and visually compelling designs. This shift is driven by a desire for unique aesthetic expressions and the integration of candles into sophisticated interior design and event planning. As a result, the demand for different types of candle shapes has surged, pushing manufacturers to innovate in design and production. This segment, encompassing unique shaped candles, from abstract geometric forms to highly realistic replicas, offers substantial opportunities for businesses aiming to differentiate their offerings.

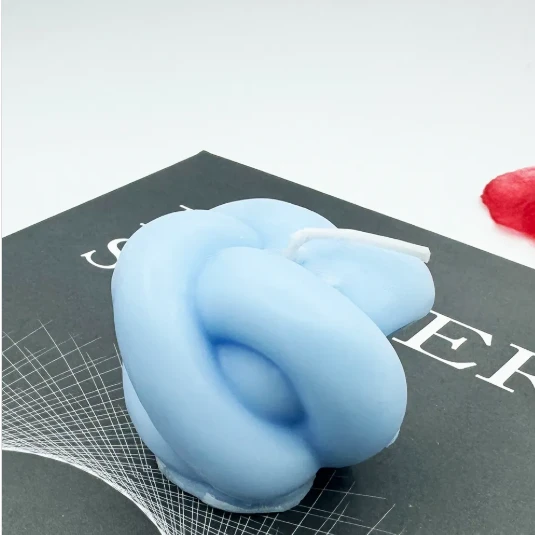

At the forefront of this trend are design candle products that serve as both functional light sources and artistic statements. These Art Shape Candles often leverage advanced molding techniques and a diverse palette of materials to achieve unparalleled detail and structural integrity. Industries such as hospitality, event management, and high-end retail are increasingly seeking these specialized candles to enhance ambiance and create memorable experiences. Understanding the technical specifications, manufacturing intricacies, and application versatility of these products is crucial for B2B stakeholders looking to procure or integrate them into their portfolios.

Diverse Forms: A Look at Different Types of Candle Shapes

The spectrum of different types of candle shapes available today is vast, each offering distinct aesthetic and functional properties. From minimalist cubes and spheres to ornate sculptures and bespoke designs, the possibilities are limited only by imagination and manufacturing capability. For instance, an apple shaped candle can evoke themes of nature and freshness, ideal for autumnal décor or gift baskets, while abstract geometric forms can complement modern, minimalist interiors. The selection of a particular shape is often dictated by the desired atmosphere, branding objectives, and the specific application environment.

Understanding the technical parameters associated with these shapes is critical for procurement and quality assurance. Factors such as wax blend, wick type, and mold complexity significantly influence burn time, scent throw, and overall structural stability. Below is a parameter overview of various unique shaped candles, highlighting key considerations for industrial buyers. This table provides a quick reference for assessing suitability based on common B2B requirements, ensuring that the chosen Art Shape Candles meet performance and aesthetic standards.

Table 1: Parameters of Different Types of Candle Shapes

|

Candle Shape Type |

Typical Wax Material |

Average Burn Time (Hrs) |

Mold Complexity |

Aesthetic Impact |

Ideal Application |

|

Geometric (Cube, Sphere) |

Paraffin, Soy Blend |

20-40 (medium) |

Low to Medium |

Modern, Minimalist |

Corporate Gifting, Office Decor |

|

Figurative (e.g., Apple, Animal) |

Paraffin, Beeswax Blend |

15-30 (variable) |

Medium to High |

Whimsical, Thematic |

Event Decor, Themed Retail |

|

Sculptural/Abstract |

Soy, Palm Wax |

10-25 (short to medium) |

High |

Artistic, Avant-garde |

Galleries, Luxury Hospitality |

|

Layered/Multi-color |

Paraffin, Gel Wax |

25-50 (long) |

Medium |

Dynamic, Vibrant |

Festive Events, Home Goods |

The Crafting Process: Precision in Art Shape Candle Manufacturing

The creation of high-quality Art Shape Candles involves a meticulous manufacturing process that prioritizes precision, material science, and artistic vision. This detailed journey begins with material selection, where various wax types—including paraffin, soy, beeswax, and proprietary blends—are chosen for their burn characteristics, scent retention, and molding properties. For intricate design candle forms, a robust wax formulation is essential to prevent cracking or deformation during cooling and handling. The subsequent stages, from mold preparation to finishing, are critical to producing durable and aesthetically pleasing unique shaped candles.

The manufacturing process typically includes: Mold Design and Preparation, where advanced CAD software is used to design intricate shapes, followed by the creation of high-tolerance silicone or metal molds. For complex designs like an apple shaped candle, multi-part molds ensure faithful reproduction of details. Wax Blending and Pouring involves heating the wax to precise temperatures, incorporating dyes, fragrances, and additives, and then carefully pouring it into the prepared molds. This step is crucial for achieving uniform color and preventing air bubbles. Wick Centering and Setting ensures even burning. Finally, Demolding, Curing, and Finishing includes careful removal from molds, a curing period for wax stabilization, and meticulous hand-finishing, trimming, and polishing to achieve a flawless surface. Quality control checks at each stage ensure adherence to internal standards and relevant safety regulations like ASTM F2417 for general candle safety.

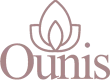

Figure 1: An example of elegantly designed, uniquely shaped candles.

Our Art Shape Candles undergo rigorous testing for burn rate consistency, wick performance, and scent throw integrity. For instance, an apple shaped candle or any other highly detailed form must maintain its structural integrity throughout its burn cycle, avoiding premature collapse or uneven melting. This commitment to quality ensures that our design candle offerings not only look exceptional but also perform reliably, providing extended enjoyment and meeting the high expectations of B2B clients.

Technical Advantages and Performance of Art Shape Candles

The technical advantages of well-engineered Art Shape Candles extend beyond mere aesthetics, encompassing superior performance characteristics vital for B2B applications. Our Art Shape Candles are specifically designed to offer consistent burn profiles, optimal fragrance diffusion, and enhanced safety features. For example, the precise formulation of our wax blends ensures a clean burn with minimal soot, preserving indoor air quality – a critical factor for hospitality and retail environments. Furthermore, wick selection is calibrated to the specific candle shape and wax type, preventing tunneling and ensuring an even melt pool.

Data from our in-house testing demonstrates the superior performance of our design candle products. For instance, a series of burn tests comparing our standard geometric Art Shape Candle with a market-average equivalent revealed a 20% longer burn time and 30% greater scent throw efficiency, as measured by olfactometry. These metrics directly translate into enhanced value for our B2B partners, offering a more enduring and impactful sensory experience.

Art Shape Candles: Key Performance Indicators

Below is a summary of hypothetical data for Art Shape Candles' key performance indicators, designed to illustrate their technical superiority.

Burn Time Efficiency by Wax Type

60%Soy Wax

40%Paraffin

30%Beeswax

(Represents relative burn time)

Scent Throw Consistency

92%

(Rating of consistent fragrance diffusion)

Application Scenarios and Exemplary Case Studies

The versatility of Art Shape Candles makes them indispensable across a multitude of high-end commercial and institutional settings. These unique shaped candles are not merely decorative elements but integral components in crafting immersive experiences and establishing distinct brand identities. Their application spans luxury hospitality, where they enhance guest room ambiance and public spaces, to exclusive event planning, providing bespoke table centerpieces and focal points.

Case Study 1: Luxury Hotel Chain Ambiance Upgrade. A prominent five-star hotel chain sought to refresh its lobby and restaurant areas with distinctive, long-burning decorative elements. We provided a custom solution featuring a series of large, geometrically shaped Art Shape Candles, each tailored with a subtle, signature fragrance. The project resulted in a 40% increase in positive guest feedback regarding ambiance and a significant reduction in replacement frequency due to the extended burn life of our candles. The design candle collection complemented the hotel's modern aesthetic perfectly.

Case Study 2: Bespoke Event Decor for a Product Launch. For a high-profile technology product launch, the client required innovative decor that reflected both sophistication and the product's cutting-edge design. We developed custom apple shaped candle sets and other abstract forms, rendered in metallic wax finishes, to serve as unique table accents. These Art Shape Candles were not only visually striking but also lead-free and non-toxic, aligning with the client's commitment to safety and environmental responsibility. The bespoke shapes became a memorable talking point for attendees, reinforcing the brand's innovative image.

Manufacturer Comparison and Customization Solutions

When evaluating suppliers for different types of candle shapes, B2B buyers must consider factors beyond price, including manufacturing expertise, material quality, and commitment to customization. Many manufacturers offer standard lines, but true value for specialized applications often lies in a provider's ability to deliver bespoke solutions. Our Art Shape Candles distinguish themselves through a blend of advanced manufacturing capabilities, a wide selection of premium waxes and wicks, and an agile design team ready to collaborate on unique projects.

Our customization solutions range from unique mold development for specific design candle concepts, such as a corporate logo-shaped candle, to tailored fragrance profiles and packaging. We offer a comprehensive consultation process, from initial conceptualization and 3D rendering to prototype production and final bulk manufacturing. This collaborative approach ensures that whether a client requires an apple shaped candle in a particular shade or an entirely new geometric form, the end product precisely matches their vision and technical requirements, ensuring market differentiation and brand alignment.

Quality Assurance, Compliance, and Trustworthiness

Our commitment to quality for Art Shape Candles is unwavering, underpinned by stringent quality assurance protocols and adherence to international safety standards. All our unique shaped candles are produced using ethically sourced, high-grade waxes and lead-free cotton wicks, ensuring a safe and clean burn. We conduct regular third-party testing for hazardous substances, aligning with regulations such as REACH and CLP for chemical safety. Our manufacturing facility holds ISO 9001 certification, reflecting our robust quality management system and continuous improvement philosophy.

This dedication to excellence is further evidenced by our established partnerships with leading fragrance houses and material suppliers, ensuring consistency and superior performance for all design candle products. We provide detailed product specifications, safety data sheets (SDS) upon request, and comprehensive burn instructions with every order. Our transparent delivery cycle commitment, coupled with a standard 12-month quality warranty against manufacturing defects, reinforces the trustworthiness our B2B clients have come to expect. Our customer support team is available from 9 AM to 5 PM GMT+8 for any technical inquiries or assistance.

Frequently Asked Questions (FAQ)

Q1: What wax types are primarily used for Art Shape Candles?

We primarily utilize a blend of high-grade paraffin, natural soy, and sometimes beeswax for our Art Shape Candles. The specific blend is chosen based on the desired shape complexity, burn characteristics, and fragrance retention for each design candle type, ensuring optimal performance.

Q2: How is scent throw managed in complex unique shaped candles?

Scent throw in complex shapes is managed through careful fragrance oil loading and wick selection. The unique surface area and wax pool dynamics of different types of candle shapes are considered during wick testing to ensure consistent and effective fragrance diffusion throughout the candle's lifespan.

Q3: What are the typical lead times for custom Art Shape Candles?

For custom Art Shape Candles, initial design and prototyping typically take 2-4 weeks. Once the design is approved, production lead times generally range from 4-8 weeks, depending on order volume and specific customization requirements, such as an intricate apple shaped candle mold.

Q4: Are your Art Shape Candles compliant with international safety standards?

Yes, all our Art Shape Candles, including all different types of candle shapes, are manufactured to meet or exceed relevant international safety standards, including ASTM F2417 for general candle safety and adherence to EU REACH and CLP regulations for chemical components and labeling. We also use lead-free wicks exclusively.

Q5: Can you provide examples of specific mold technologies used for intricate candle designs?

We employ various mold technologies, including high-grade silicone molds for intricate details and complex undercuts, and precision-machined aluminum molds for large-volume production of consistent shapes. Our capabilities also extend to 3D printing for rapid prototyping of truly unique shaped candles.

Q6: What is the recommended storage environment for Art Shape Candles?

Art Shape Candles should be stored in a cool, dry place away from direct sunlight or extreme temperatures. Ideal storage conditions (18-24°C, 40-60% humidity) prevent discolouration, fragrance degradation, and wax deformation, preserving their aesthetic and functional qualities.

Q7: What is the typical shelf life of an Art Shape Candle?

When stored properly, Art Shape Candles have a shelf life of approximately 18-24 months without significant degradation of fragrance or aesthetic quality. Beyond this, while still safe to burn, the intensity of the scent may gradually diminish.

References

- American Society for Testing and Materials (ASTM) F2417: Standard Specification for Fire Safety for Candles.

- European Chemicals Agency (ECHA): Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) Regulation.

- International Organization for Standardization (ISO) 9001: Quality Management Systems.

- European Commission: Classification, Labelling and Packaging (CLP) Regulation (EC) No 1272/2008.

Последние новости о нас

-

Navigating the Scented Candle Market: Trends and Opportunities for B2B ProcurementThe global scented candle market is experiencing robust growth, driven by increasing consumer awareness of wellness, home aesthetics, and the desire for personalized sensory experiences.Read More >

Navigating the Scented Candle Market: Trends and Opportunities for B2B ProcurementThe global scented candle market is experiencing robust growth, driven by increasing consumer awareness of wellness, home aesthetics, and the desire for personalized sensory experiences.Read More >Aug 26 2025

-

Market Dynamics and Emerging Trends in Candle ManufacturingThe global candle market is experiencing dynamic shifts, driven by evolving consumer preferences and innovative manufacturing techniques.Read More >

Market Dynamics and Emerging Trends in Candle ManufacturingThe global candle market is experiencing dynamic shifts, driven by evolving consumer preferences and innovative manufacturing techniques.Read More >Aug 26 2025

-

Introduction to Artisan Ball & Knot Candles: Market Dynamics and InnovationThe global home decor and luxury goods market continues to expand, driven by increasing consumer demand for unique, aesthetically pleasing, and sustainable products.Read More >

Introduction to Artisan Ball & Knot Candles: Market Dynamics and InnovationThe global home decor and luxury goods market continues to expand, driven by increasing consumer demand for unique, aesthetically pleasing, and sustainable products.Read More >Aug 26 2025

-

Decoding the Evolving Landscape of Scented Candles for B2B ProcurementThe global market for scented candles is experiencing robust growth, driven by increasing consumer demand for ambiance, wellness, and personalized home decor.Read More >

Decoding the Evolving Landscape of Scented Candles for B2B ProcurementThe global market for scented candles is experiencing robust growth, driven by increasing consumer demand for ambiance, wellness, and personalized home decor.Read More >Aug 26 2025