Navigating the Scented Candle Market: Trends and Opportunities for B2B Procurement

Navigating the Scented Candle Market: Trends and Opportunities for B2B Procurement

The global scented candle market is experiencing robust growth, driven by increasing consumer awareness of wellness, home aesthetics, and the desire for personalized sensory experiences. For B2B buyers, understanding the nuances of procuring bulk scented candles, developing ароматизированные свечи на заказ, or sourcing specialized options like small scented candles for hospitality, or seasonal winter scented candles, is crucial. This segment is characterized by innovations in wax blends, fragrance formulations, and sustainable packaging. Market analysts project a CAGR of approximately 6.5% from 2023 to 2030, highlighting a significant opportunity for businesses to integrate high-quality, appealing scented candles into their product lines, marketing strategies, or operational environments. Key drivers include the rise of e-commerce, increasing disposable incomes in emerging economies, and a growing emphasis on creating comforting and luxurious atmospheres in both commercial and residential settings.

Beyond traditional retail, the B2B demand for scented candles extends to luxury hotels, spas, corporate gifting programs, event planners, and private label brands seeking unique product differentiation. The shift towards natural and eco-friendly ingredients is also a prominent trend, with soy, coconut, and beeswax blends gaining traction over traditional paraffin waxes. This focus on sustainability not only appeals to environmentally conscious consumers but also offers manufacturers opportunities to enhance brand reputation and comply with evolving regulatory standards. Businesses that strategically partner with manufacturers capable of delivering both quality and compliance will be well-positioned to capitalize on these market dynamics, offering their clients or end-users a superior product experience.

Technical Parameters and Core Specifications of Scented Candles

Understanding the technical parameters of scented candles is paramount for B2B procurement, ensuring product performance, safety, and compliance with industry standards. These specifications determine the candle's burn quality, scent throw, and overall lifespan. Key parameters include wax type, wick material, fragrance load, and container design. Manufacturers often adhere to standards such as ASTM F2417 (Standard Specification for Fire Safety for Candle Products) and IFRA (International Fragrance Association) guidelines for fragrance safety. When sourcing bulk scented candles or developing ароматизированные свечи на заказ, detailed attention to these specifications prevents issues such as tunneling, excessive soot, or inadequate scent diffusion, which can impact end-user satisfaction and brand reputation.

|

Key Scented Candle Technical Specifications |

|||

|

Parameter |

Description |

Typical Range/Value |

Impact on Performance |

|

Wax Type |

Soy, Coconut, Paraffin, Beeswax blends |

Varied melt points (e.g., Soy: 49-52°C) |

Burn time, scent throw, soot production, sustainability. |

|

Wick Material & Size |

Cotton (braided, flat), Wood (crackle, no-crackle) |

Optimized for candle diameter and wax type |

Even burn pool, flame height, soot, consistent scent release. |

|

Fragrance Load |

Percentage of fragrance oil in wax |

Typically 6-12% (wt/wt) |

Scent intensity (hot and cold throw), wax stability. |

|

Burn Time (Estimated) |

Duration candle burns under optimal conditions |

20-80+ hours (depending on size) |

Product value, user experience, perceived quality. |

|

Материал контейнера |

Glass, Ceramic, Tin, Concrete |

Heat resistant, non-porous |

Safety, aesthetic appeal, heat distribution, reusability. |

|

Scent Throw (Hot & Cold) |

Strength of fragrance when unlit (cold) and lit (hot) |

Subjective (light, medium, strong) |

User satisfaction, suitability for room size, brand appeal. |

Advanced Manufacturing Process for Scented Candles

The production of high-quality scented candles, whether bulk scented candles or highly specialized ароматизированные свечи на заказ, involves a sophisticated multi-stage process optimized for consistency, safety, and performance. Our manufacturing adheres to stringent quality control standards, including internal protocols aligned with ISO 9001, to ensure every candle meets expectations. This meticulous process ensures superior product integrity and sensory experience, setting our offerings apart in the B2B market.

-

Raw Material Sourcing & Inspection:We meticulously select premium waxes (e.g., 100% natural soy wax, coconut wax blends) and IFRA-certified fragrance oils, ensuring they are free from phthalates and parabens. Wicks are chosen based on wax type and container dimensions, often lead-free cotton or sustainably sourced wood. Each batch undergoes chemical analysis to confirm purity and suitability, a critical step for products like small scented candles where consistency is key.

-

Wax Melting & Blending:Wax is precisely melted in controlled environments to avoid overheating, which can degrade its properties. Fragrance oils are then added at specific temperatures, typically between 80-85°C, and meticulously blended for several minutes to ensure even distribution. This temperature control is vital for achieving optimal 'hot throw' and preventing fragrance degradation.

-

Wick Centering & Securing:Pre-tabbed wicks are carefully secured to the bottom of clean, pre-heated containers. Advanced wick centering tools are employed to ensure perfect vertical alignment, which is crucial for an even burn and preventing tunneling. For winter scented candles, wick type might be adjusted to accommodate heavier fragrance oils and potentially thicker wax blends for optimal burn.

-

Pouring:The blended wax is poured into containers at an exact temperature, typically 65-75°C, to minimize air bubbles and ensure a smooth, even surface. Automated pouring machines guarantee precise fill volumes and reduce variations across large batches of bulk scented candles.

-

Curing:Candles are allowed to cure for a minimum of 7-14 days in a temperature-controlled environment. This essential period allows the wax and fragrance molecules to bind effectively, significantly enhancing the scent throw and overall burn quality. Skipping or shortening this step can result in poor scent diffusion and inconsistent burning.

-

Trimming & Finishing:Wicks are trimmed to the optimal length (typically 1/4 inch or 6mm) for safe and efficient burning. Each candle undergoes a final visual inspection for surface finish, wick placement, and container integrity. Any imperfections are addressed before packaging.

-

Quality Control & Testing:A percentage of each batch undergoes comprehensive burn testing (e.g., according to ASTM standards for flame height, soot production, burn rate) and scent throw evaluation. Our facilities are regularly audited to ensure compliance with relevant industry and safety standards, providing peace of mind for B2B partners. Typical lifespan ranges from 40-60 hours for a 200g candle, with variations based on specific product design.

Application Scenarios and Technical Advantages

Scented candles serve diverse B2B applications, from enhancing brand ambiance to creating memorable gifts. Our products offer distinct technical advantages that translate into superior value for our clients. For instance, the consistent burn rate and exceptional scent throw of our bulk scented candles make them ideal for large-scale retail or hospitality settings, ensuring uniform quality across thousands of units.

Typical Application Scenarios:

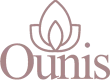

- Hospitality Industry:Luxury hotels, spas, and resorts utilize small scented candles in guest rooms, lobbies, and treatment areas to create a welcoming and serene atmosphere. Our candles are designed for extended, clean burns, minimizing maintenance for staff.

- Corporate Gifting & Promotional Items:Businesses leverage ароматизированные свечи на заказ as high-end corporate gifts, employee appreciation tokens, or promotional items, often branded with company logos or specific fragrances.

- Retail & Private Label:Retailers and e-commerce brands procure bulk scented candles for private labeling, offering unique scent profiles and aesthetic designs that align with their brand identity.

- Seasonal & Event Merchandising:Specialized winter scented candles, with notes of pine, cinnamon, or cedarwood, are popular for holiday seasons, while other custom scents cater to specific events or themes.

- Home Decor & Interior Design:Designers use scented candles as essential elements to complete interior aesthetics, complementing visual design with ambient fragrance.

Technical Advantages:

- Optimized Scent Throw:Our proprietary wax blends and precise fragrance infusion techniques ensure a balanced and robust scent throw, both when cold and lit, filling spaces effectively without being overwhelming.

- Clean & Even Burn:Expertly wicked candles minimize soot and tunneling, guaranteeing a full, even melt pool and maximizing burn time, enhancing both safety and product longevity. This is critical for small scented candles which require precise wick selection.

- Premium & Safe Ingredients:We utilize IFRA-compliant fragrance oils and natural, non-toxic wax bases (e.g., soy, coconut), ensuring a safer product for consumers and adherence to international health standards.

- Durability & Longevity:Rigorous testing ensures our candles maintain their fragrance integrity and burn quality throughout their advertised lifespan, offering reliable performance.

- Customization Capability:With state-of-the-art facilities, we offer extensive customization for ароматизированные свечи на заказ, including bespoke fragrance development, container selection, and personalized labeling.

These technical advantages translate directly into benefits for our B2B partners, offering products that are not only aesthetically pleasing but also reliable, safe, and cost-effective in the long run due to their superior performance and consistency. Our commitment to quality ensures that our bulk scented candles and custom solutions deliver exceptional value across all applications.

Manufacturer Comparison and Customization Solutions

Selecting the right manufacturer for bulk scented candles or ароматизированные свечи на заказ is a critical decision for B2B entities. The market is populated with various suppliers, each with differing capabilities in terms of production scale, customization options, quality control, and compliance. A thorough comparison based on specific needs, such as lead times for small scented candles or complex fragrance development for winter scented candles, is essential. Our commitment to transparent processes, stringent quality assurance, and a client-centric approach positions us as a preferred partner.

Comparative Analysis:

|

Manufacturer Comparison Criteria for Scented Candles |

||

|

Criterion |

Our Company Offerings |

Typical Competitor |

|

Wax Quality & Variety |

Premium natural waxes (Soy, Coconut, Beeswax blends); certified sustainable. |

Often paraffin-dominant, limited natural options, less certifications. |

|

Fragrance Compliance |

100% IFRA-compliant, phthalate & paraben-free, detailed SDS. |

May lack full IFRA compliance or transparency on chemical composition. |

|

Customization Depth |

Full bespoke options: fragrance, container, label, packaging. Low MOQ for custom. |

Limited customization, high MOQ, pre-set designs/fragrances. |

|

Quality Control & Certification |

ISO 9001 certified processes, ASTM F2417 burn testing, SGS audited. |

Varying QC, less formal certifications, inconsistent testing. |

|

Lead Times (Bulk Orders) |

Efficient production lines, 4-6 weeks for large orders. |

Often 8-12+ weeks, prone to delays, less flexible. |

|

Customer Support & Warranty |

Dedicated account managers, post-sale support, clear defect warranty. |

Limited support, unclear policies, reactive instead of proactive. |

Customization Solutions:

Our facility excels in providing comprehensive customization solutions for ароматизированные свечи на заказ, enabling brands to create unique product offerings that resonate with their target audience. This includes:

- Bespoke Fragrance Development:Our in-house perfumers can craft exclusive scent profiles, from subtle notes for small scented candles to rich, complex aromas for winter scented candles, ensuring brand exclusivity.

- Container & Packaging Design:A wide range of container materials (glass, ceramic, metal, concrete) and custom packaging options (boxes, sleeves, labels) are available to match brand aesthetics.

- Wax Blend Formulation:Custom wax blends can be developed to achieve specific burn characteristics, scent throw, or sustainability goals (e.g., higher percentage of recycled waxes).

- Minimum Order Quantity (MOQ) Flexibility:We offer competitive MOQs to support businesses of all sizes, from startups to established brands needing bulk scented candles.

This level of customization, combined with our rigorous quality control, ensures that partners receive products that not only meet but exceed their specifications and market expectations.

Case Studies and Industry Trustworthiness

Our track record in delivering high-quality bulk scented candles and bespoke solutions builds trust with our B2B clientele. We pride ourselves on long-term partnerships, reflected in positive client feedback and successful project implementations. Our authoritative position in the market is underpinned by robust industry certifications, transparent processes, and unwavering commitment to customer satisfaction.

Application Cases:

- Luxury Hotel Chain Partnership:A prominent luxury hotel chain commissioned small scented candles for over 2,000 guest rooms across their properties. We developed a signature calming lavender-eucalyptus blend, ensuring a consistent scent profile and clean burn essential for a premium guest experience. The project was delivered ahead of schedule, with a 99.8% quality adherence rate as per their post-delivery audit.

- Retail Brand Private Label Launch:A fast-growing e-commerce home goods brand sought to launch a private label line of winter scented candles. We collaborated closely on developing festive fragrances, selecting sustainable coconut wax, and designing bespoke container aesthetics. The initial order of 50,000 units was produced and delivered within 7 weeks, contributing to a 25% increase in their holiday season sales.

- Corporate Gifting Program:A global tech company required 10,000 ароматизированные свечи на заказ for their annual client appreciation program. We developed a sophisticated "innovation" scent and customized elegant packaging featuring their corporate branding. Feedback indicated high recipient satisfaction, with many commenting on the unique fragrance and premium quality.

Our Trustworthiness Pillars:

- Industry Certifications:We operate under ISO 9001:2015 certified quality management systems. Our fragrances comply with IFRA standards, and our products meet relevant safety standards such as ASTM F2417. We can provide documentation for REACH and RoHS compliance upon request.

- Transparent Delivery & Logistics:We provide clear delivery schedules (typically 4-8 weeks for bulk orders, depending on customization) and use reputable logistics partners to ensure timely and secure arrival of bulk scented candles

- Comprehensive Warranty & Support:All products are backed by a satisfaction guarantee. In the unlikely event of manufacturing defects, we offer a clear return and replacement policy, ensuring peace of mind for our partners. Our dedicated customer support team is available from concept to post-delivery.

- Years of Experience:With over 15 years in the scented candle manufacturing industry, we bring unparalleled expertise and a deep understanding of market demands and technical requirements.

Frequently Asked Questions (FAQ)

Q1: What is 'Fragrance Load' in scented candles?

A1: Fragrance load refers to the percentage of fragrance oil added to the wax mixture. A higher fragrance load typically results in a stronger scent throw. Our standard is 8-10%, optimized for maximum scent throw without compromising burn quality for our bulk scented candles.

Q2: What are the differences between various wax types (e.g., Soy, Paraffin, Coconut)?

A2: Soy wax is a natural, biodegradable alternative derived from soybeans, offering a cleaner burn and longer lifespan. Paraffin wax, a petroleum byproduct, provides a strong scent throw but can produce more soot. Coconut wax is also natural, burns slowly, and has excellent scent retention. Blends often combine properties to optimize performance for specific products like small scented candles.

Q3: How do you ensure the safety of your fragrance oils?

A3: All our fragrance oils are sourced from reputable suppliers and are certified by the International Fragrance Association (IFRA) for safety. They are free from phthalates, parabens, and restricted chemicals, ensuring they are safe for use in residential and commercial environments, including winter scented candles.

Q4: What is 'wicking' and why is it important?

A4: Wicking refers to the process of selecting and correctly placing the wick in a candle. Proper wicking is crucial for an even burn pool, preventing tunneling, excessive soot, and ensuring a consistent flame height, directly impacting the scent throw and overall performance of ароматизированные свечи на заказ.

Q5: What are your Minimum Order Quantities (MOQs) for custom orders?

A5: Our MOQs for ароматизированные свечи на заказ vary depending on the level of customization and specific components required. We strive to be flexible and competitive, often starting from 500 units for fully customized designs, and lower for variations of existing products. Please contact us for a detailed quote.

Q6: Do your candles comply with international shipping regulations?

A6: Yes, our products are designed and packaged to meet international shipping standards. We provide necessary documentation, including Safety Data Sheets (SDS), and can advise on specific compliance for various regions for bulk scented candles shipments.

Q7: What is the typical lead time from order confirmation to delivery?

A7: For standard bulk scented candles orders, lead times typically range from 4-6 weeks. For highly ароматизированные свечи на заказ with new fragrance development or unique packaging, it may extend to 8-12 weeks. We work closely with clients to establish realistic timelines and communicate progress transparently.

References

- International Fragrance Association (IFRA) Standards.

- ASTM International, Standard Specification for Fire Safety for Candle Products (ASTM F2417).

- International Organization for Standardization (ISO) 9001:2015.

- Reports on Global Scented Candle Market Growth & Trends, Grand View Research (2023 Update).

- European Chemicals Agency (ECHA) - REACH and CLP Regulations.

Последние новости о нас

-

Market Dynamics and Emerging Trends in Candle ManufacturingThe global candle market is experiencing dynamic shifts, driven by evolving consumer preferences and innovative manufacturing techniques.Read More >

Market Dynamics and Emerging Trends in Candle ManufacturingThe global candle market is experiencing dynamic shifts, driven by evolving consumer preferences and innovative manufacturing techniques.Read More >Aug 26 2025

-

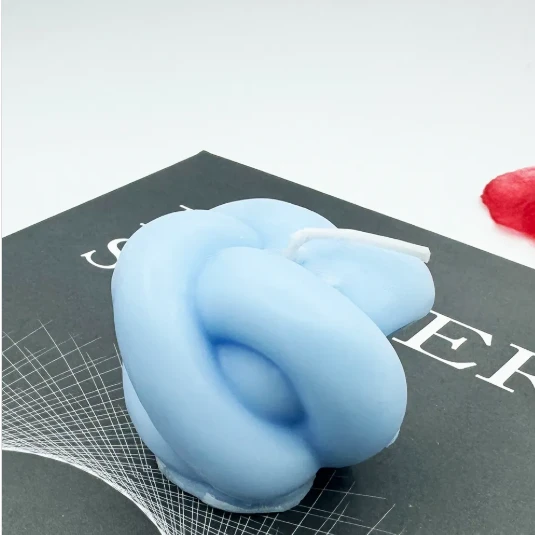

Introduction to Artisan Ball & Knot Candles: Market Dynamics and InnovationThe global home decor and luxury goods market continues to expand, driven by increasing consumer demand for unique, aesthetically pleasing, and sustainable products.Read More >

Introduction to Artisan Ball & Knot Candles: Market Dynamics and InnovationThe global home decor and luxury goods market continues to expand, driven by increasing consumer demand for unique, aesthetically pleasing, and sustainable products.Read More >Aug 26 2025

-

Exploring the Evolving Landscape of Art Shape CandlesThe market for decorative candles has witnessed a significant transformation, moving beyond traditional pillars and votives to embrace intricate and visually compelling designs.Read More >

Exploring the Evolving Landscape of Art Shape CandlesThe market for decorative candles has witnessed a significant transformation, moving beyond traditional pillars and votives to embrace intricate and visually compelling designs.Read More >Aug 26 2025

-

Decoding the Evolving Landscape of Scented Candles for B2B ProcurementThe global market for scented candles is experiencing robust growth, driven by increasing consumer demand for ambiance, wellness, and personalized home decor.Read More >

Decoding the Evolving Landscape of Scented Candles for B2B ProcurementThe global market for scented candles is experiencing robust growth, driven by increasing consumer demand for ambiance, wellness, and personalized home decor.Read More >Aug 26 2025