Market Dynamics and Emerging Trends in Candle Manufacturing

Market Dynamics and Emerging Trends in Candle Manufacturing

The global candle market is experiencing dynamic shifts, driven by evolving consumer preferences and innovative manufacturing techniques. Businesses across hospitality, retail, and event management are increasingly seeking specialized candle solutions. From the cost-efficiency and versatility of bulk unscented candles for large-scale events to the exquisite craftsmanship of luxury scented candles designed for premium spaces, manufacturers are adapting to diverse demands. The rise of niche markets, such as personalized gifting and themed celebrations, has also propelled the demand for mini scented candles and distinctive products like birthday cake scented candles. Understanding these trends is crucial for B2B procurement, ensuring alignment with end-user expectations and optimizing operational efficiencies.

Technological advancements in wax formulations, fragrance encapsulation, and wick materials are enhancing product performance and sustainability. Manufacturers are investing in automation to achieve consistent quality and scale production, whether for vast quantities of bulk unscented candles or the intricate designs required for luxury scented candles. Furthermore, stringent regulatory standards, particularly concerning fragrance safety (IFRA) and chemical composition (REACH), are shaping product development, pushing for eco-friendly and health-conscious options. This section delves into the specific parameters and applications that define success in today's competitive candle market, offering insights for informed decision-making.

Precision Manufacturing: From Raw Material to Finished Product

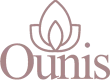

The manufacturing process for high-quality scented and unscented candles is a multi-stage operation demanding precision and adherence to strict quality control. It begins with the careful selection of raw materials, including waxes (soy, paraffin, beeswax, coconut, palm), fragrance oils (for scented varieties), and wicks (cotton, wood). For bulk unscented candles, the focus is on achieving a clean, consistent burn with minimal smoke, often utilizing paraffin or a soy-paraffin blend for cost-effectiveness and excellent burn characteristics. In contrast, luxury scented candles frequently employ premium natural waxes like soy or coconut, paired with complex, IFRA-certified fragrance blends to ensure a robust 'hot throw' and 'cold throw.'

The core manufacturing steps involve wax melting, fragrance blending (for scented candles), wicking, pouring, and curing. Wax is precisely heated to its optimal pouring temperature to prevent imperfections like 'wet spots' or 'frosting.' Fragrance oils are added at specific temperatures to ensure even dispersion and preserve their integrity, particularly critical for vibrant birthday cake scented candles or delicate mini scented candles. Wicks are centrally placed and secured to ensure an even 'burn pool' and prevent 'tunneling.' After pouring into containers, candles undergo a crucial 'curing' period, typically 1-2 weeks, allowing the wax and fragrance molecules to bind, enhancing scent throw and burn performance. Rigorous testing, adhering to ASTM standards for burn time, flame height, and soot production, ensures each batch meets stringent quality benchmarks.

Applicable industries for these diverse candle types span a wide range. Event management and hospitality sectors frequently utilize bulk unscented candles for their ambient lighting capabilities without interfering with culinary aromas. Premium hotels, spas, and boutique retailers are prime consumers of luxury scented candles, leveraging their sophisticated fragrances to enhance brand identity and customer experience. For corporate gifting, wedding favors, and personalized promotions, mini scented candles offer a versatile and elegant solution. Niche applications like bakeries, party supply stores, and gift shops are the primary market for novelty items such as birthday cake scented candles, which provide a unique sensory experience. Product lifespan typically ranges from 25-60 hours per 8oz candle, depending on wax type and wick performance, ensuring prolonged use and value.

Technical Parameters and Product Comparison

Selecting the right candle product requires a detailed understanding of key technical parameters. Factors such as wax blend, fragrance load, wick type, and container material directly influence burn performance, scent throw, and safety. For instance, bulk unscented candles prioritize extended burn times and stable flame characteristics, often achieved with harder wax blends and optimized wick sizes. Luxury scented candles, conversely, balance robust fragrance throw with a clean burn, frequently employing softer natural waxes and complex essential oil blends. Below is a comparative overview of typical parameters across various candle categories.

Candle Product Specification Comparison

|

Category |

Primary Wax Type |

Fragrance Load (Max) |

Avg. Burn Time (8oz) |

Материал контейнера |

Typical Application |

|

Bulk Unscented Candles |

Paraffin / Soy Blend |

N/A (0%) |

50-60 hours |

Glass, Pillar, Votive |

Events, Restaurants, Hospitality |

|

Luxury Scented Candles |

Soy / Coconut / Beeswax Blend |

8-12% |

40-50 hours |

High-end Glass, Ceramic |

Spas, Boutiques, Corporate Gifting |

|

Mini Scented Candles |

Soy / Paraffin Blend |

6-10% |

15-20 hours (3oz) |

Small Glass, Tin |

Wedding Favors, Travel, Samplers |

|

Birthday Cake Scented Candles |

Paraffin / Soy Blend |

7-11% |

30-40 hours (6oz) |

Themed Glass, Ceramic |

Party Supplies, Gifting, Specialty Retail |

The technical advantages of custom-manufactured candles are significant. For large venues, the consistent burn rate and minimal residue of high-quality bulk unscented candles reduce maintenance and replacement costs. For brands aiming for a premium experience, the precise scent throw and elegant presentation of luxury scented candles directly enhance brand perception and customer loyalty. Custom wick selection, for example, is critical for controlling 'burn pool' diameter, preventing 'tunneling,' and ensuring optimal 'hot throw' for scented varieties. Furthermore, advanced wax blends can be engineered for extended burn times or enhanced fragrance diffusion, delivering superior performance over generic alternatives.

Scented Candle Market Share by Wax Type (Illustrative Data)

This illustrative data reflects current market trends, highlighting the shift towards natural and blended waxes for scented candles due to consumer preferences for sustainability and cleaner burn properties. This data can be visually represented in a pie chart to easily convey market dominance.

|

Wax Type |

Market Share (%) |

|

Soy Wax |

40% |

|

Парафиновый воск |

30% |

|

Soy/Coconut Blends |

15% |

|

Пчелиный воск |

8% |

|

Other Natural Waxes |

7% |

Data is illustrative and reflects general market trends; actual figures may vary by region and specific product segment.

Customization Solutions and Application Case Studies

Tailored candle solutions are essential for businesses seeking to create unique brand experiences or meet specific operational needs. Our customization programs encompass wax blends, fragrance development, wick selection, container design, and packaging. For a chain of upscale restaurants, we developed custom bulk unscented candles in elegant glass holders, ensuring a long, clean burn that provided ambient lighting without competing with the culinary aromas. The client reported a 20% reduction in replacement frequency due to the optimized burn rate and high-quality wax.

Another successful project involved a luxury hotel brand seeking distinctive luxury scented candles for their lobby and guest suites. We collaborated closely with their branding team to formulate an exclusive signature scent—a blend of cedarwood, amber, and bergamot—using IFRA-compliant fragrance oils and a premium coconut-soy wax blend. The candles were housed in bespoke ceramic vessels, reflecting the hotel's sophisticated aesthetic. Post-implementation surveys indicated a significant increase in guest satisfaction scores related to room ambiance, with over 30% of guests inquiring about purchasing the candles. Similarly, a leading event planner leveraged our expertise for their high-profile corporate galas, opting for customized mini scented candles as exquisite parting gifts, tailored to each event's theme and recipient demographics.

The demand for innovative novelty candles is also growing, as demonstrated by a recent partnership with a national bakery chain. We designed a range of birthday cake scented candles that perfectly captured the essence of vanilla frosting and warm sponge cake, packaged in festive, eco-friendly boxes. These candles became a top-selling add-on product, enhancing the customer's birthday experience and boosting the bakery's ancillary revenue by 15% within the first quarter. These cases underscore the importance of a flexible manufacturing partner capable of translating specific business needs into high-performing candle products, ensuring brand consistency and market differentiation.

Frequently Asked Questions (FAQ)

Q1: What is 'cold throw' and 'hot throw' in candle terminology?

'Cold throw' refers to the scent emitted by a candle when it is unlit at room temperature. 'Hot throw' is the scent released when the candle is actively burning. Achieving a balanced and potent hot throw is crucial for luxury scented candles, requiring careful formulation of fragrance load and wax type.

Q2: How does wax blend impact candle performance and burn time?

Different wax blends offer distinct characteristics. Paraffin provides excellent scent throw and vivid color but is petroleum-based. Soy wax is natural, burns cleaner, and has a longer burn time but may have a softer scent throw. Blends (e.g., soy-coconut) combine advantages, optimizing for both burn duration, scent diffusion, and sustainability, essential for both bulk unscented candles and high-end scented varieties.

Q3: What is 'tunneling' and how can it be prevented?

Tunneling occurs when a candle burns down its center, leaving un-melted wax around the edges of the container. This is typically due to an undersized wick or insufficient burn time during initial use. Proper wick selection for the container diameter and wax type, along with advising customers to burn candles for 2-4 hours on the first light to achieve a full 'melt pool', can prevent tunneling, especially crucial for uniform consumption of bulk unscented candles.

Q4: Are your fragrances IFRA compliant and materials REACH certified?

Yes, all our fragrance oils are sourced from reputable suppliers and are IFRA (International Fragrance Association) compliant, ensuring safety for intended use. Our raw materials, including waxes and dyes, adhere to strict regulatory standards such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) for chemical safety and environmental responsibility. This is particularly important for products like luxury scented candles and birthday cake scented candles that come into close contact with users.

Q5: What is the typical lead time for custom candle orders?

Lead times vary based on order volume, customization complexity, and current production schedules. For standard bulk unscented candles or mini scented candles, lead times typically range from 4-6 weeks. Highly customized luxury scented candles requiring unique molds or extensive fragrance development may require 8-12 weeks. We provide detailed timelines upon quote finalization.

Q6: Do you offer samples for bespoke fragrance development?

Absolutely. For luxury scented candles and other custom scented projects, we offer a fragrance sampling and refinement process. This iterative approach allows clients to evaluate scent profiles in their intended environment, ensuring the final product perfectly aligns with their brand vision and desired 'hot throw' performance before full-scale production commences.

Q7: What is your quality assurance and warranty policy?

Our manufacturing process adheres to ISO 9001 quality management principles, with every batch undergoing rigorous testing for burn performance, safety, and aesthetic quality, consistent with ASTM standards. We offer a 1-year warranty against manufacturing defects from the date of delivery. Our dedicated customer support team is available to address any concerns promptly, ensuring complete satisfaction with your order of bulk unscented candles, mini scented candles, or any other specialized product.

Authoritative References

- American Society for Testing and Materials (ASTM) F2417. "Standard Specification for Fire Safety for Candles."

- International Fragrance Association (IFRA) Standards. "Guidelines for the Safe Use of Fragrance Ingredients."

- European Chemicals Agency (ECHA). "Regulation (EC) No 1907/2006 on the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH)."

- National Candle Association (NCA). "Best Practices for Candle Manufacturing and Safety."

- Global Market Insights. "Scented Candles Market Size, Share & Forecast, 2023 – 2032."

Последние новости о нас

-

Navigating the Scented Candle Market: Trends and Opportunities for B2B ProcurementThe global scented candle market is experiencing robust growth, driven by increasing consumer awareness of wellness, home aesthetics, and the desire for personalized sensory experiences.Read More >

Navigating the Scented Candle Market: Trends and Opportunities for B2B ProcurementThe global scented candle market is experiencing robust growth, driven by increasing consumer awareness of wellness, home aesthetics, and the desire for personalized sensory experiences.Read More >Aug 26 2025

-

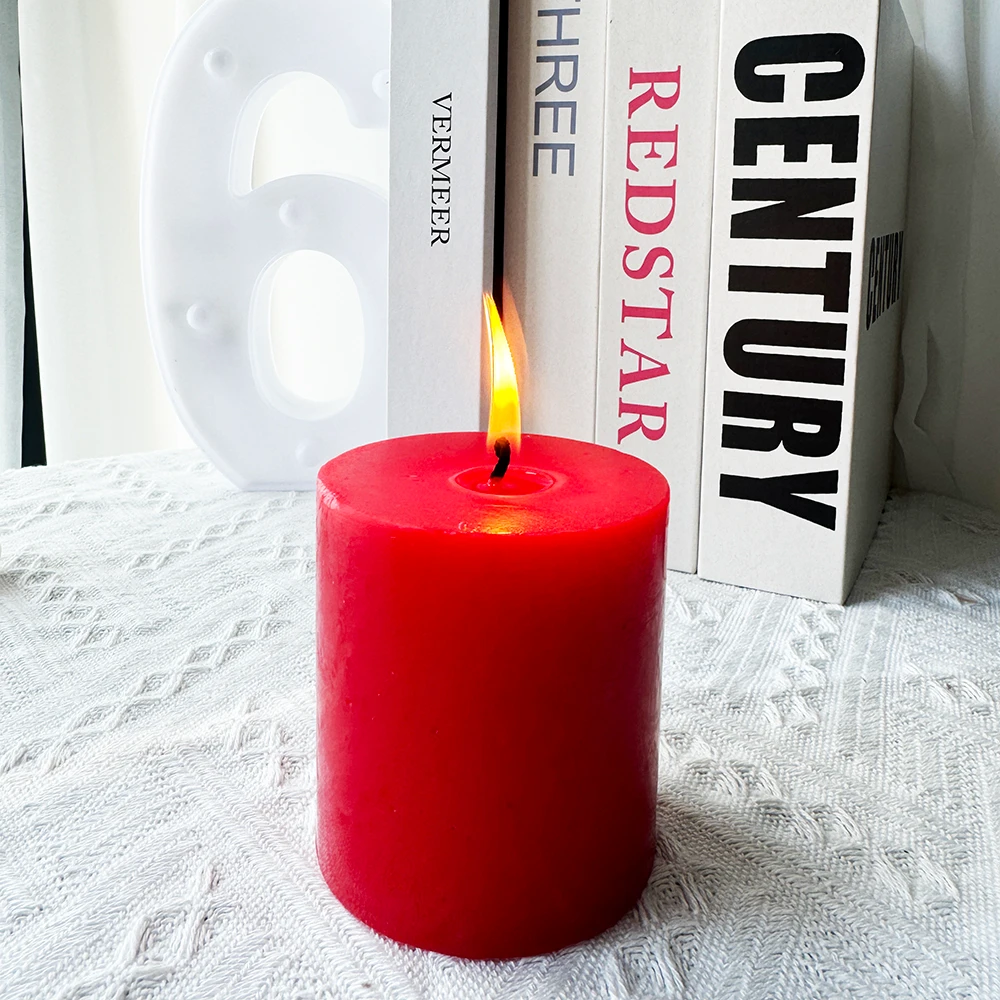

Introduction to Artisan Ball & Knot Candles: Market Dynamics and InnovationThe global home decor and luxury goods market continues to expand, driven by increasing consumer demand for unique, aesthetically pleasing, and sustainable products.Read More >

Introduction to Artisan Ball & Knot Candles: Market Dynamics and InnovationThe global home decor and luxury goods market continues to expand, driven by increasing consumer demand for unique, aesthetically pleasing, and sustainable products.Read More >Aug 26 2025

-

Exploring the Evolving Landscape of Art Shape CandlesThe market for decorative candles has witnessed a significant transformation, moving beyond traditional pillars and votives to embrace intricate and visually compelling designs.Read More >

Exploring the Evolving Landscape of Art Shape CandlesThe market for decorative candles has witnessed a significant transformation, moving beyond traditional pillars and votives to embrace intricate and visually compelling designs.Read More >Aug 26 2025

-

Decoding the Evolving Landscape of Scented Candles for B2B ProcurementThe global market for scented candles is experiencing robust growth, driven by increasing consumer demand for ambiance, wellness, and personalized home decor.Read More >

Decoding the Evolving Landscape of Scented Candles for B2B ProcurementThe global market for scented candles is experiencing robust growth, driven by increasing consumer demand for ambiance, wellness, and personalized home decor.Read More >Aug 26 2025